You demand a cooling solution that delivers efficiency and reliability. The OUMAL OMC-30A 30 Ton Split Air Cooled Chiller System meets these needs with advanced energy-saving technology and eco-friendly refrigerants. Its split design simplifies installation and supports a wide range of industries. You benefit from robust performance, easy maintenance, and a chiller built for today’s commercial environments. OUMAL stands behind its products with a strong commitment to quality.

Key Takeaways

-

The OUMAL OMC-30A chiller system offers energy efficiency, helping you reduce operational costs and lower energy bills.

-

Its split design allows for flexible installation, making it suitable for various building layouts and space constraints.

-

The chiller ensures reliable performance with advanced controls, minimizing downtime and maintaining optimal cooling.

-

Easy maintenance features, like detachable panels, simplify inspections and repairs, saving you time and effort.

-

Customization options allow you to tailor the chiller to meet specific cooling needs in commercial and industrial settings.

Air Cooled Chiller System Overview

What Is a Split Chiller

You encounter many types of chillers in commercial settings. Air cooled chillers remain a popular choice because they operate outdoors and circulate chilled water efficiently. Water-cooled chillers require indoor installation and cooling towers, making them less common for many businesses. Split systems offer a unique solution when space is limited or direct expansion cooling is needed away from exterior walls.

| Chiller Type | Description | Location | Adoption Rate |

| Air-Cooled Chillers | Located outdoors, contains all refrigeration components, circulates chilled water. | Outdoor | Commonly used |

| Water-Cooled Chillers | Located indoors, requires a cooling tower, more efficient for larger applications. | Indoor | Less common |

| Split Systems | Components split between indoor and outdoor units, used when space is limited. | Indoor/Outdoor | Increasingly popular |

Split chillers divide their components between two units. The indoor unit includes the air circulation fan, evaporator coil, and expansion device. The outdoor unit contains the condensing coil, compressor, and condenser fan. You benefit from flexible installation options, especially in buildings with limited exterior access.

Key Features of OUMAL OMC-30A

You demand performance and reliability from your air cooled chiller system. The OUMAL OMC-30A delivers with a robust cooling capacity of 81 kW, ensuring rapid temperature reduction for your equipment and processes. This chiller uses eco-friendly refrigerants such as R22, R407C, R410A, and R134A, helping you meet international environmental standards.

OUMAL OMC-30A stands out with its split structure, microcomputer control, and comprehensive protection devices. You experience quiet operation indoors, with noise levels below 40dB, and efficient heat exchange thanks to high-quality plate heat exchangers. The temperature adjustment range extends from 5ºC to 35ºC, giving you precise control over your cooling needs.

Tip: You can request customization to match your specific load and application requirements. OUMAL offers flexible options to ensure your air cooled chillers fit your business perfectly.

| Feature | OUMAL OMC-30A | Industry Standard |

| Structure | Split structure | Varies (integrated/split) |

| Control | Microcomputer control | Varies |

| Noise Level | <30-40dB (indoor), 60-70dB (outdoor) | Typically <50dB (indoor) |

| Protection Devices | Comprehensive (multiple protections) | Basic protections |

| Temperature Adjustment Range | 5ºC to 35ºC | 5ºC to 30ºC |

| Pipe Material | 304 stainless steel, copper tubes | Varies |

| Heat Exchange Efficiency | High-efficiency plate heat exchangers | Standard heat exchangers |

| Maintenance | Easy with detachable panels | Varies |

You gain easy maintenance with detachable panels and durable materials like stainless steel and copper tubes. The air-cooled chillers from OUMAL provide high heat exchange efficiency, supporting your operations in demanding environments. With these features, you secure a reliable and adaptable chiller for your commercial or industrial needs.

Cooling Challenges for Chillers

Modern commercial buildings face several cooling challenges that impact operational costs and occupant comfort. You must address energy costs, space limitations, changing demands, and maintenance requirements to keep your facility running efficiently. These challenges affect industries such as malls, hotels, factories, and laboratories, where optimal temperature control is essential for productivity and safety.

Energy Efficiency

You strive to maximize energy efficiency in your building. Cooling systems account for up to 15% of total energy use in commercial spaces. High energy consumption often results from overcooling, neglecting economizer modes, and failing to shut down equipment during cooler periods. When temperatures rise by just 1°C, cooling energy use can increase by 7.6% to 9.8%. Maintaining optimal working conditions between 70-73 degrees Fahrenheit supports concentration and motivation. If you experience insufficient cooling, you may notice fatigue and reduced cognitive function among staff. Chiller troubleshooting becomes critical when you want to reduce costs and improve cooling efficiency.

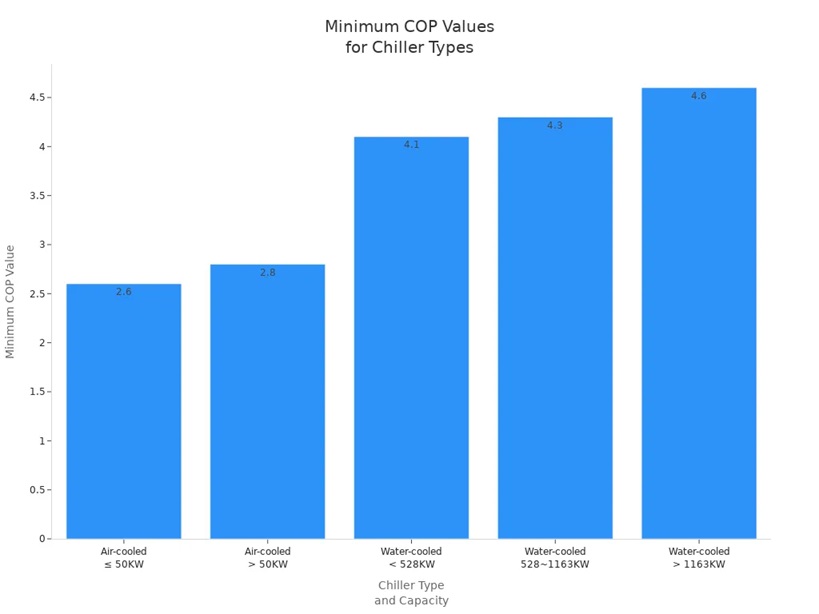

| Chiller Type | Energy Efficiency Description |

| Water-Cooled Chillers | More energy efficient due to lower refrigerant condensing temperatures, resulting in reduced compressor workload. |

| Air-Cooled Chillers | Less energy efficient as the condensing temperature is dependent on ambient dry-bulb temperature, leading to higher energy consumption. |

Space and Installation

Space constraints present another challenge. You need chillers that fit your building’s layout and mechanical rooms. Air-cooled chillers take up less space and do not require cooling towers, making installation faster and more flexible. These chillers use fans to move air across condenser coils, releasing heat outdoors. You often install them in smaller buildings or areas with limited mechanical room space. Chiller troubleshooting steps include evaluating ductwork and airflow to ensure proper installation and cooling efficiency.

| Aspect | Air-Cooled Chillers |

| Installation Speed | Faster to install |

| Space Requirements | Takes up less mechanical room space |

| Cooling Tower Requirement | Does not require cooling towers |

| Maintenance Demands | Lower maintenance demands, beneficial for water-scarce regions |

Scalability

You require scalable cooling solutions that adapt to your business growth. Split air cooled chillers offer modular designs, allowing you to expand capacity as your needs change. High-capacity chillers with compact designs free up rooftop space, making it easier to scale your cooling system. You can add more units or upgrade existing ones without major disruptions. Chiller troubleshooting steps help you assess current and future cooling requirements, ensuring your system remains efficient.

-

Scalable cooling systems manage current needs and prepare for future increases.

-

Modular chillers allow easy expansion for growing data centers or production lines.

-

Compact designs free up valuable building space.

Maintenance

Maintenance remains a top concern for facility managers. You encounter common chiller problems such as refrigerant leaks, high-pressure discharges, and airflow obstructions. Regular chiller troubleshooting steps include monitoring for unusual noises, excessive vibration, and friction. Split air cooled chillers often require less frequent maintenance if you manage environmental factors and keep condenser coils clear. Addressing insufficient cooling and performing routine checks help you avoid downtime and maintain cooling efficiency.

-

Monitor refrigerant levels and pressure.

-

Inspect for airflow obstructions and clean condenser coils.

-

Listen for unusual noises and vibration.

-

Schedule regular maintenance checks.

Tip: Proactive chiller troubleshooting steps reduce the risk of breakdowns and extend the life of your cooling system.

Solutions with Air-Cooled Chillers

Efficiency and Cost Savings

You want your facility to run efficiently while keeping operational costs low. The OUMAL OMC-30A air cooled chiller system delivers strong solutions for energy savings. This chiller uses advanced compressors and high-efficiency plate heat exchangers to maximize cooling performance. You benefit from lower energy bills because the system adjusts output based on demand. The use of eco-friendly refrigerants like R22, R407C, R410A, and R134A helps you meet environmental standards and reduce your carbon footprint.

You also save on water costs. Air-cooled chillers do not require cooling towers or water pumps, which means you avoid extra expenses and maintenance. The split design further reduces installation costs, making it easier to fit the chiller into your building’s layout. Over time, these features combine to provide efficient chiller operation and long-term cost savings.

Tip: Choosing an air cooled chiller system with a split design can help you control both energy and water expenses, especially in regions where water is scarce.

Flexible Installation

You need solutions that adapt to your building’s unique requirements. The OUMAL OMC-30A offers flexible installation options thanks to its split structure. You can place the indoor and outdoor units in locations that best suit your space, whether you have limited mechanical room or need to avoid exterior wall modifications. This flexibility makes the system ideal for retrofits, new construction, or facilities with unusual layouts.

You also gain the ability to scale your cooling system as your needs grow. The modular nature of air-cooled chillers allows you to add more units or upgrade capacity without major disruptions. You can expand your system to support new equipment or increased occupancy, ensuring that your cooling solutions keep pace with your business.

-

Place indoor and outdoor units where they fit best.

-

Expand your system easily as your cooling needs increase.

-

Adapt to changing building layouts or future renovations.

Reliable Performance

You expect your chiller to deliver consistent cooling and prevent downtime. The OUMAL OMC-30A addresses common reliability issues found in traditional chillers. Many systems suffer from improper operation, maintenance neglect, or incorrect sizing, which can lead to reduced efficiency and frequent breakdowns. The table below shows how the OUMAL OMC-30A provides solutions to these challenges:

| Common Issue | Description | OUMAL OMC-30A Solution |

| Improper Operation | Poor operating practices can reduce efficiency and lifespan. | Microcomputer control ensures optimal system performance. |

| Maintenance Neglect | Lack of proper maintenance increases energy use and causes performance issues. | Easy access panels and clear maintenance alerts simplify chiller maintenance. |

| Incorrect Sizing | Undersized or oversized units cause inefficiencies. | Customization options let you match the chiller to your exact load. |

You benefit from advanced microcomputer controls that monitor and adjust system performance automatically. The OUMAL OMC-30A uses high-quality materials and components, which means you get reliable cooling even in demanding environments. The 15-month warranty gives you peace of mind, knowing that your investment is protected.

Easy Maintenance

You want to minimize downtime and keep your cooling system running smoothly. The OUMAL OMC-30A makes chiller maintenance straightforward. Detachable panels provide quick access to internal components, so you can perform inspections and repairs without hassle. The system uses durable materials like stainless steel and copper tubes, which resist corrosion and extend the life of your chiller.

Routine checks become easier with clear maintenance alerts and user-friendly controls. You can monitor refrigerant levels, inspect for airflow obstructions, and clean condenser coils with minimal effort. These features help you prevent downtime and maintain optimal cooling performance year-round.

Note: Regular chiller maintenance not only extends equipment life but also ensures efficient operation and reliable system performance.

By choosing the OUMAL OMC-30A air cooled chiller system, you secure solutions that address energy efficiency, installation flexibility, reliable performance, and easy maintenance. You gain a cooling system designed for modern commercial needs.

Applications of Chiller Systems

Commercial Uses

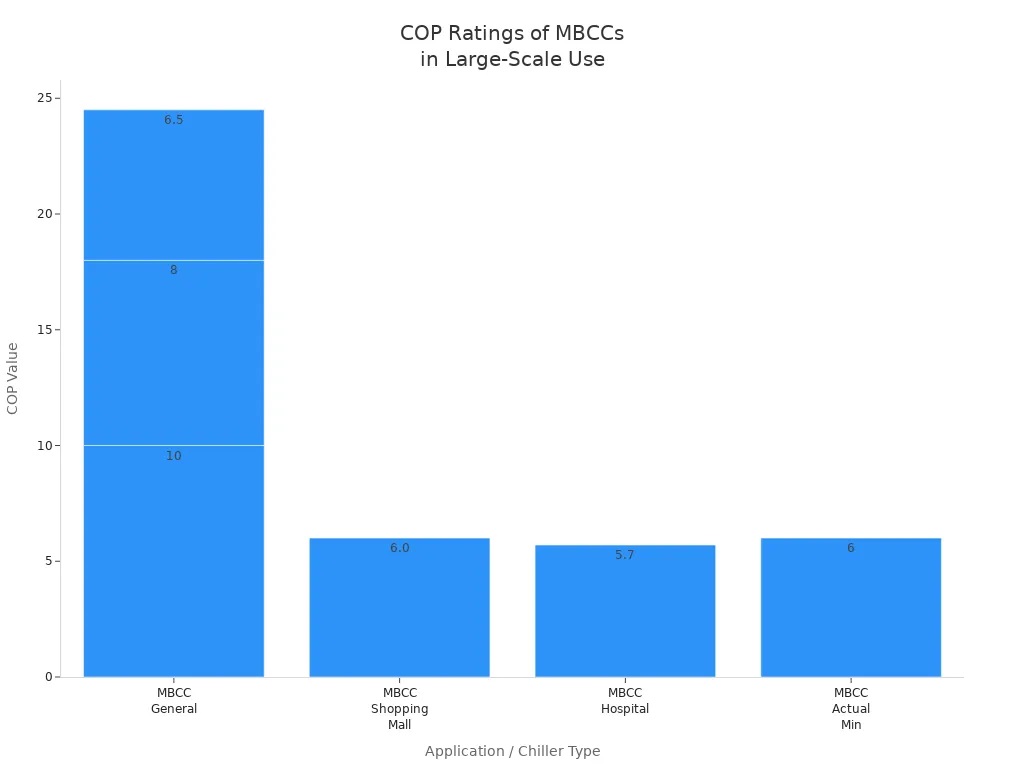

You rely on a chiller system to maintain comfort and efficiency in a wide range of commercial environments. Shopping malls, hotels, and hospitals all require precise temperature control to ensure customer satisfaction and protect sensitive equipment. Data centers, which now number over 10,000 worldwide, depend on effective cooling to support servers and prevent downtime. These facilities use about 30% of their total energy for cooling alone, making efficient chiller operation essential.

You also see chiller systems in office buildings, retail complexes, and educational institutions. These locations demand energy-efficient solutions that meet regulatory standards and reduce operational costs. The OUMAL OMC-30A adapts to these needs with flexible installation and customizable features. You can request specific refrigerants or temperature ranges to match your building’s requirements.

Tip: You can optimize your chiller system for any commercial space by choosing the right configuration and controls.

Industrial Uses

You depend on a chiller to support critical processes in industrial settings. Factories, laboratories, and production lines require stable temperatures for quality control and safety. Industries such as plastics, electronics, textiles, and food processing all benefit from reliable cooling.

The table below highlights key industrial applications and the performance metrics you value most:

| Industrial Applications | Performance Metrics |

| Medical | Efficiency |

| Brewery | Reliability |

| Laboratories | Capacity |

| Blow Molding | Energy Consumption |

You can customize your chiller system to fit unique industrial needs. OUMAL offers options such as single or multiple compressors, specific refrigerants, adjustable temperature ranges, and tailored power supply configurations. These features help you achieve optimal performance in chemical processing, electronics manufacturing, and food and beverage production.

| Customization Option | Description | Industry Applications |

| Single or Multiple Compressors | Operate alternately based on load changes for better energy efficiency | Chemical processing, food and beverage, electronics manufacturing |

| Specific Refrigerants | Choose refrigerants for your application | Various industrial applications |

| Temperature Ranges | Adjust temperature settings for your process | Chemical processing, food and beverage production |

| Power Supply Configurations | Match power supply to your facility | Electronics manufacturing, chemical industry |

You gain a chiller system that adapts to your industry’s demands, whether you manage a laboratory, a brewery, or a large-scale manufacturing plant. OUMAL’s customization ensures your cooling solution fits your exact requirements.

You see how the OUMAL OMC-30A 30 Ton Split Air Cooled Chiller System meets your commercial cooling demands. You benefit from:

-

Energy efficiency that lowers your operating costs

-

Flexible installation for different building layouts

-

Reliable performance in demanding environments

-

Easy maintenance that saves you time

Consider OUMAL when you need a chiller that delivers consistent results and supports your business growth.