Batteries are key components in modern energy storage systems, widely used in various fields such as electric vehicles, portable electronic devices, and large - scale energy storage. Electrochemical electrolytic cells, as devices that convert electrical energy into chemical energy, have a significant impact on battery research. They can be used to simulate the internal electrochemical processes of batteries, study the properties of electrode materials, and explore new battery systems, which are of great significance for promoting the development of battery technology.

1. Working Principle of Electrochemical Electrolytic Cells

An electrochemical electrolytic cell is composed of two electrodes (anode and cathode) and an electrolyte solution. When an external power source is connected, the ano de undergoes an oxidation reaction, and the cathode undergoes a reduction reaction. Cations in the electrolyte move towards the cathode, and anions move towards the anode, forming an internal ion - conduction path, while electrons flow in the external circuit, completing the electrochemical reaction process. For example, in an electrolytic cell with inert electrodes electrolyzing copper chloride solution, at the anode, chloride ions are oxidized to chlorine gas, and at the cathode, copper ions are reduced to copper metal.

2.Application in Studying Battery Electrochemical Reactions

2.1 Cyclic Voltammetry Analysis

Cyclic voltammetry is a common method using electrochemical electrolytic cells to study battery electrochemical reactions. By applying a cyclic - varying potential between the working electrode and the counter - electrode in the electrolytic cell, the current response is measured. This method can be used to determine the redox potential of electrode materials, study the reaction mechanism of electrode processes, and evaluate the reversibility of electrochemical reactions. For example, in the research of lithium - ion batteries, cyclic voltammetry can be used to analyze the lithium - ion insertion and extraction processes of positive and negative electrode materials, and to determine the optimal potential range for battery operation.

2.2 Impedance Spectroscopy

Electrochemical impedance spectroscopy is another important technique. An alternating - current signal is applied to the electrolytic cell, and the impedance of the electrochemical system is measured at different frequencies. Through impedance analysis, information about the charge - transfer resistance, diffusion resistance, and double - layer capacitance of the electrode/electrolyte interface can be obtained. This is of great help for understanding the internal resistance of the battery, the ion - diffusion process in the electrode material, and the stability of the solid - electrolyte interphase (SEI) film. For instance, in the study of sodium - ion batteries, impedance spectroscopy can be used to analyze the influence of different electrolytes on the charge - transfer process of hard - carbon electrodes.

3. Application in Evaluating Electrode Materials

3.1 Screening of Positive Electrode Materials

Electrochemical electrolytic cells are widely used in the screening of positive electrode materials for batteries. Different metal oxides, phosphates, etc., can be used as positive electrode materials for testing. By comparing their electrochemical performance in electrolytic cells, such as specific capacity, cycle stability, and rate performance, excellent positive electrode materials can be selected. For example, in the research of lithium - ion batteries, electrolytic cells are used to test the performance of lithium cobaltate, lithium nickel - manganese - cobalt oxide (NMC), and lithium iron phosphate (LFP) materials. The results show that LFP has the advantages of high safety and long - cycle life, while NMC has a higher energy density.

3.2 Research on Negative Electrode Materials

For negative electrode materials, electrolytic cells also play a crucial role. Take silicon - based negative electrode materials for lithium - ion batteries as an example. Due to their high theoretical specific capacity, they have attracted much attention, but they also face the problem of large - volume expansion. Through electrolytic cell experiments, the lithiation and delithiation processes of silicon - based materials can be studied, and methods to improve their cycle stability, such as coating and nano - structuring, can be explored. In addition, in the research of hard - carbon negative electrode materials for sodium - ion batteries, electrolytic cells can be used to study the influence of different anions in electrolytes on the electrochemical performance of hard - carbon, so as to optimize the electrolyte formula.

3.3 Evaluation of New Electrode Materials

With the continuous development of battery technology, new types of electrode materials are constantly emerging, such as sulfur - based materials for lithium - sulfur batteries and organic electrode materials. Electrochemical electrolytic cells provide a platform for evaluating their performance. By setting up appropriate electrolytic cell systems, the electrochemical properties of these new materials, including their specific capacity, coulombic efficiency, and rate performance, can be accurately evaluated, which is conducive to promoting their practical application.

4. Application in Battery Preparation and Optimization

4.1 Pre - lithiation/Pre - sodiumation Process

In lithium - ion and sodium - ion batteries, pre - lithiation and pre - sodiumation processes are important steps to improve battery performance. Electrochemical electrolytic cells can be used to realize these processes. For example, in the pre - lithiation of silicon - based negative electrodes, an electrolytic cell can be used to deposit a certain amount of lithium on the silicon electrode surface in advance, which can improve the first - coulombic efficiency of the battery and increase the capacity retention rate. In a study, through electrolytic pre - lithiation, the capacity retention rate of NMC111||Si full - cells in the 100th cycle was significantly increased from 54% to 78%.

4.2 Electrolyte Optimization

Electrochemical electrolytic cells can also be used to optimize electrolytes. By changing the composition, concentration, and additive of the electrolyte, and then testing the electrochemical performance of the battery in the electrolytic cell, the optimal electrolyte formula can be obtained. For example, by adding certain additives to the electrolyte, the stability of the SEI film can be improved, the charge - transfer resistance can be reduced, and the cycle performance of the battery can be enhanced.

5. Application in Waste Battery Recycling

5.1 Selective Extraction of Active Substances

With the large - scale application of batteries, the problem of waste battery treatment has become increasingly prominent. Electrochemical electrolytic cells can be used for the selective extraction of active substances in waste batteries. For example, inspired by the charging process of lithium iron phosphate positive electrode materials, electrochemical methods can theoretically achieve selective lithium extraction from waste lithium iron phosphate. Through the design of an appropriate electrolytic cell system, lithium ions in waste lithium iron phosphate can be extracted into the electrolyte under the action of an electric field, and then recovered through methods such as precipitation or ion - exchange, realizing the recycling of lithium resources.

5.2 Coupling with Hydrogen Production

In addition to the extraction of active substances, waste battery recycling can also be coupled with hydrogen production. For example, in a system using phosphomolybdic acid as a redox medium, while selectively extracting lithium from waste lithium iron phosphate, water in the cathode chamber is decomposed to produce hydrogen. This not only realizes the recycling of waste batteries but also produces clean energy hydrogen, which has good economic and environmental benefits.

6. Experimental Methods and Key Technologies of Electrochemical Electrolytic Cells in Battery Research

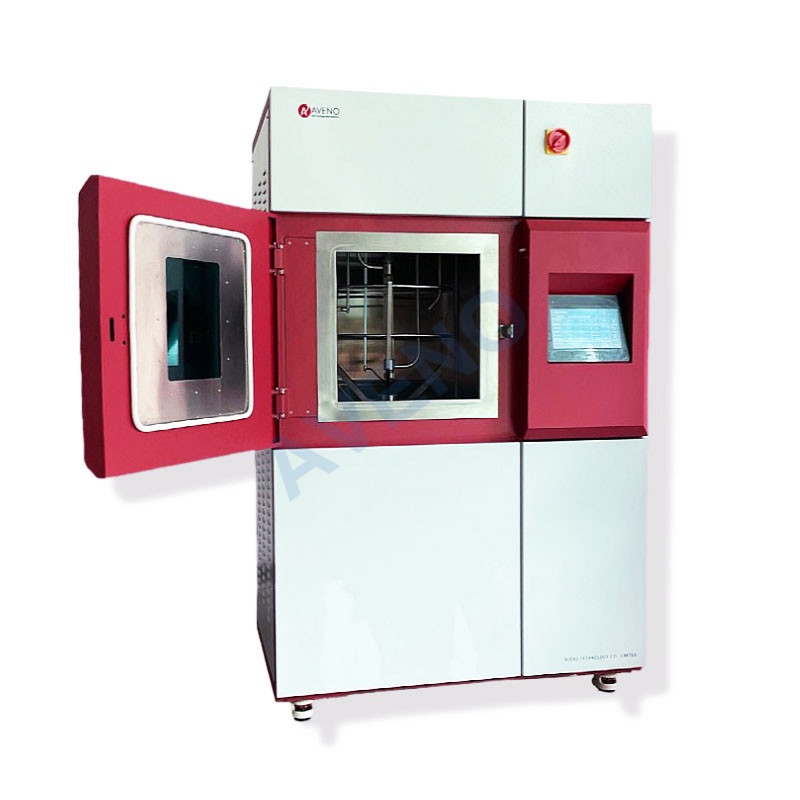

6.1 Cell Design and Assembly

According to different research purposes, appropriate electrolytic cell designs are required. Common ones include two - electrode cells and three - electrode cells. Three - electrode cells can more accurately measure the potential and current of the working electrode by introducing a reference electrode, which is suitable for in --depth research on electrode reactions. During cell assembly, attention should be paid to the selection of electrodes, electrolytes, and separators, as well as the control of assembly conditions to ensure the stability and repeatability of the experimental results.

6.2 Selection of Electrolytes and Electrodes

The selection of electrolytes is crucial for the performance of electrolytic cells. It is necessary to consider factors such as ionic conductivity, chemical stability, and compatibility with electrode materials. For example, organic electrolytes are commonly used in lithium - ion batteries, while aqueous electrolytes may be used in some sodium - ion batteries or aqueous battery systems. The electrode material should be selected according to the research object, and its particle size, morphology, and porosity will all affect the experimental results.

6.3 Data Acquisition and Analysis

During the operation of the electrolytic cell, a large amount of data such as potential, current, and impedance are generated. Professional electrochemical workstations are usually used for data acquisition. After data acquisition, appropriate data - analysis methods are required, such as fitting impedance data with an equivalent circuit model to obtain relevant electrochemical parameters, and analyzing cyclic voltammetry curves to study reaction mechanisms.

Electrochemical electrolytic cells have a wide range of applications in battery research, covering many aspects such as the study of electrochemical reactions, the evaluation of electrode materials, battery preparation and optimization, and waste battery recycling. Through the use of electrolytic cells, researchers can deeply understand the internal mechanisms of batteries, screen out excellent electrode materials and electrolytes, optimize battery preparation processes, and realize the recycling of waste batteries. With the continuous progress of battery technology, the role of electrochemical electrolytic cells will be more important, and they will provide strong support for the development of high - performance, low - cost, and environmentally friendly battery systems. In the future, with the continuous improvement of experimental methods and the development of new technologies, electrochemical electrolytic cells are expected to play a greater role in more new battery systems and research fields.