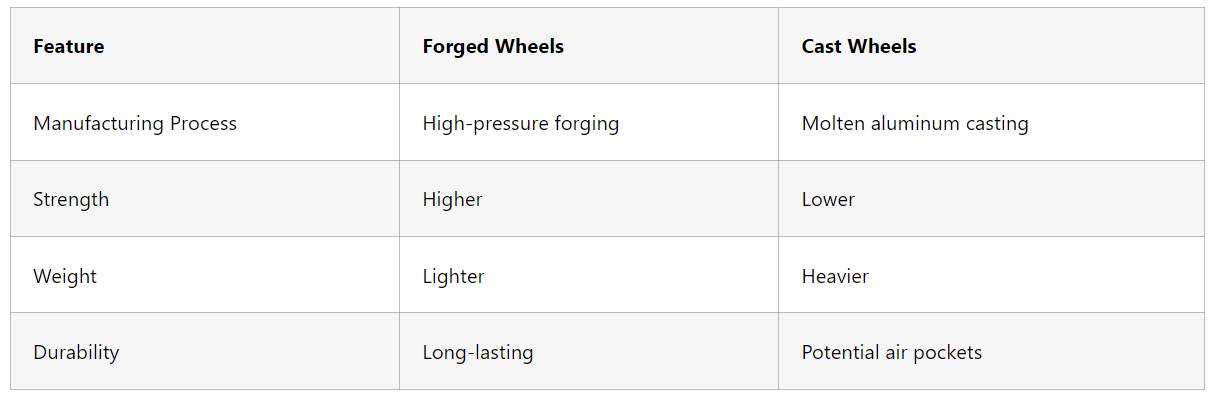

Cast wheels are made by pouring molten aluminum into a mold. This is cheaper but can leave air pockets in the wheel. These pockets make cast wheels weaker than forged ones. This affects how well they perform, last, and are reliable.

Forged wheels are also lighter than cast ones. Being lighter means better car handling and saving on fuel. Drivers who want better performance and control choose forged wheels for a better drive.

When looking at forged vs cast wheels, we see big differences in how they're made and how they perform. Drivers should think about these differences when picking wheels for their cars. This is especially true if they want better performance and longer-lasting wheels.

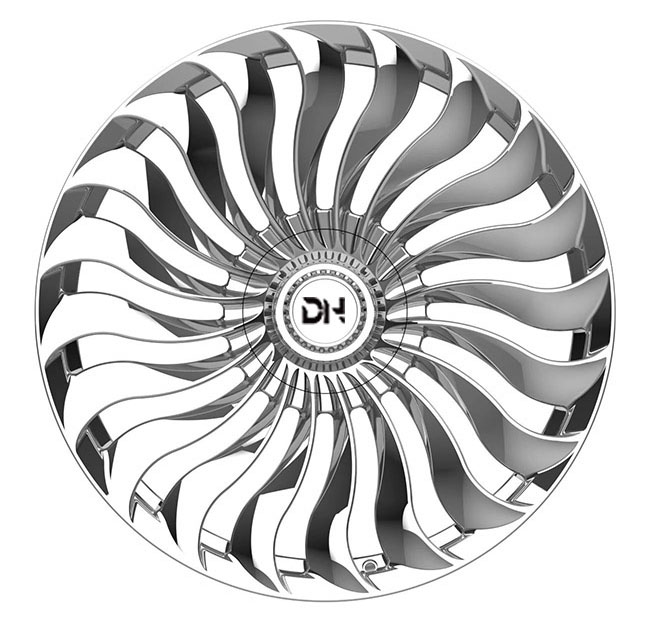

Popular Custom Forged Wheel Designs

In the world of custom forged wheels, two types are very popular. They are monoblock wheels and multi-piece forged rims. These wheels meet different needs and tastes, making them favorites among car lovers.

Monoblock Forged wheels are made from one piece of alloy. This makes them very strong and light. They are great for fast driving and racing.

They are also strong and look the same everywhere. These wheels look good and perform well.

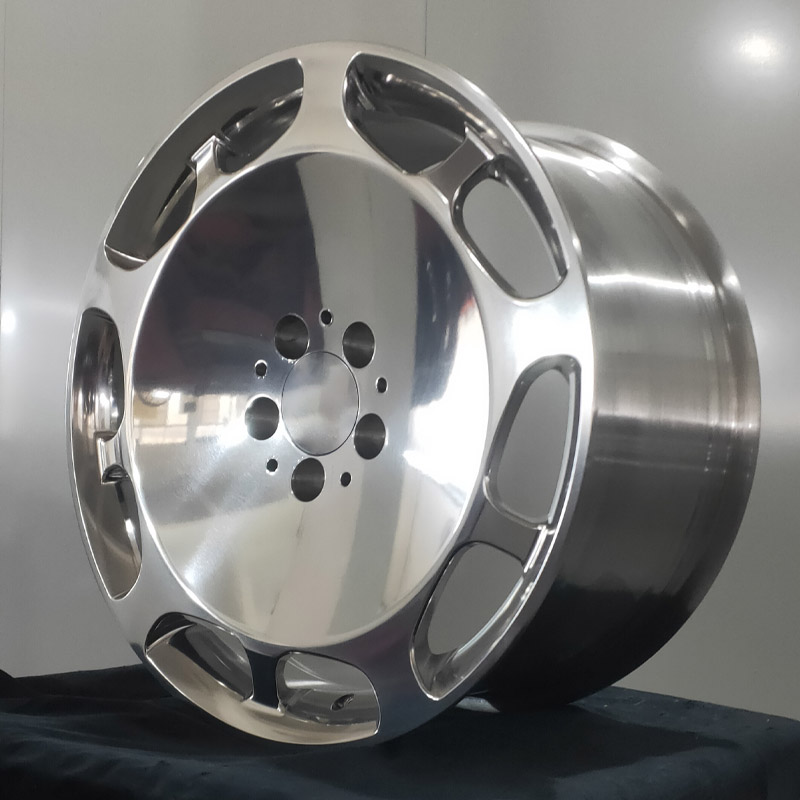

Multi-piece Forged Rims are made of two or three parts that come together. This lets you change the offset, width, and finish. It also makes fixing them easier if parts break.

They look cool and let you make your car stand out. These rims make any car look and perform better.

Which do you prefer to, forged wheels or cast wheels?