Both CNC and polishing are "cutting" the surface of the wheel hub to achieve a flat effect.But the difference lies in the scale range. If a CNC lathe can be processed at 0.1~1mm, then polishing is processed at 0.01~0.05.Because they have different depths of "knife marks" on the wheels, they have different flatness and different reflective effects. However, due to the insufficient processing depth of the polishing method, the workpiece must be processed to a certain flatness difference by a lathe before the polishing process can be done. So it stands to reason that the wheels will definitely be polished after they have been CNC refined. Otherwise, the rough turning knife marks and some bumps on the wheel rim will appear more obvious after polishing. Generally speaking, the brightness of polishing is higher than that of CNC turning. In addition, if it is a shallow scratch, if it does not penetrate the paint coating, just repair the paint. If the paint is penetrated, as mentioned earlier, polishing has almost no correction effect on the scratches, and it will only brighten the scratches, making them more obvious. It still has to be polished after the car.

Wheel Adapter

Wheel adapters are usually found in the situations which require a fitting to help to put a wheel on a vehicle. Dating back to the very beginning, the wide bolt pattern has made impossible decorative rims. As a result, this fitting are designed to bring in many benefits.

Generally speaking, the materials such as the aluminum or steel are available for manufacturing of this necessary industrial fitting for most automobiles. And in order to meet the various specifications, there is a great variety for practical use. For example, the most common type is the one designed like a heavy and flat disk. It can be attached tightly by the pre-drilling studs and others to the onside holes.

When the wheel is not normally required to be placed on a vehicle, it is wise to take the wheel adapter for help. The corn parts of this fitting are the two bolt patterns. The one is used to attach the vehicle's hub and the other is used to protrude from the adapter. As the space has been left, the new required wheel can match the vehicle conveniently and perfectly. The wheel adapter is able to excellently combine the vehicle and the wheel together by the aid of the special countersunk lug bolts and nuts.

People would wonder the safety caused by the employment of the wheel adapter. Actually, it is safe seriously under the related specifications. If the weight and size limits or other things can be totally under control, it is beneficial by adopting the wheel adapter. But there is something which needs our attentions. As this fitting is designed primarily for decorative retrofitting of aftermarket wheel, it is unwise to put it for the use of heavy hauling or hard cornering. Otherwise, unpleasant situations would occur, even some accidents. In conclusion, the selection on the specific type should be taken seriously according the specific requirements.

Why do more and more car owners choose T6061-T6 aluminum alloy forged wheels?

Mainly because of the below advantages of the aluminum alloy forged wheels :

1) Unique design.

Forged wheels are produced both according to existing templates and individual designs from the customers. You can add originality to the discs with the help of color painting (the constantly updated color range offers great opportunities in this regard), laser or mechanical engraving

2) High safety margin.

3) Low weight.

The low weight provides a smooth ride, lower fuel consumption and fast speed gain. Forged wheels have proven themselves in off-road and adverse weather conditions,

Forging weighs almost half as much as stamped steel wheels, and a third less than cast wheels. This leads to reduced load on the chassis.

4) Resistance to corrosion and the effects of road reagents.

5) Plasticity. The fiber structure improves the flexibility of the metal, so in a strong blow the rim is more likely to bend than crack.

6) Easy to install: If you want something original and reliable, forged products have the advantage. Only it is better to put them on cars with reinforced suspension.

7) Inexpensive to repair. Small deformations that may occur during use or in a traffic accident are eliminated by rolling on the machine, which are available at most service stations.

Kinder reminder:

When choosing unique forged wheels, it is imperative to take into account the seating diameter, rim width, size and configuration of mounting holes, rim outreach (affects the width of the track), maximum load.

FYI, custom forged wheels can be made in different size from 15” to 32”, even bigger.

Wish the above information is helpful to the lovers of forged wheels.

Why do people love forged wheels more than cast ones?

The advantages of forged wheels:

1. Aluminum alloy forged wheels are known for their strength and performance.

2.Lightweight forged rims make your car faster and handle better.

3.You can choose from many designs for looks and function.

4.Forged wheels are made under high pressure for strength and efficiency.

What are Forged Wheels?

Forged wheels show off amazing engineering skills. They are the top in wheel technology. They start with a solid piece of aluminum alloy, called a billet. Then, this billet is shaped into a wheel under huge pressure.

Forged wheels are different from cast ones. Cast wheels melt metal and pour it into a mold. But forged wheels keep the metal's natural strength. This makes them not just lighter but also much stronger.

When making forged wheels, special CNC milling machines are used. These machines make detailed and precise patterns. These patterns look luxurious and perform well, making each wheel a mix of beauty and function.

Forged wheels are made for lasting durability and strength. They are loved in the car world for these reasons. They are the top pick for those who want style and efficiency in their driving.

Benefits of Forged Wheels

Forged wheels are great for car lovers. They are made with strong alloys and precise methods for top performance. These wheels last longer, are lighter, and can be customized.

Durability

The forged wheel durability is top-notch. The special process used makes the wheels strong and tough. They can take a lot of driving stress without losing performance.

Weight Reduction

These wheels are made to be very light. This makes the car lighter, which means better gas mileage and smoother driving.

Customization

There are many custom forged wheel designs to choose from. You can pick the size and finish that fits your style. Brands like Vossen, BBS, and HRE offer many options. They mix looks with great performance.

Best Forged Wheels for Premium Performance

For car lovers in Singapore, picking the right wheels can make a big difference. We’ll talk about the top forged wheels from well-known brands. These wheels are known for their top-notch performance and look.

That's why the best forged wheels are a big deal.

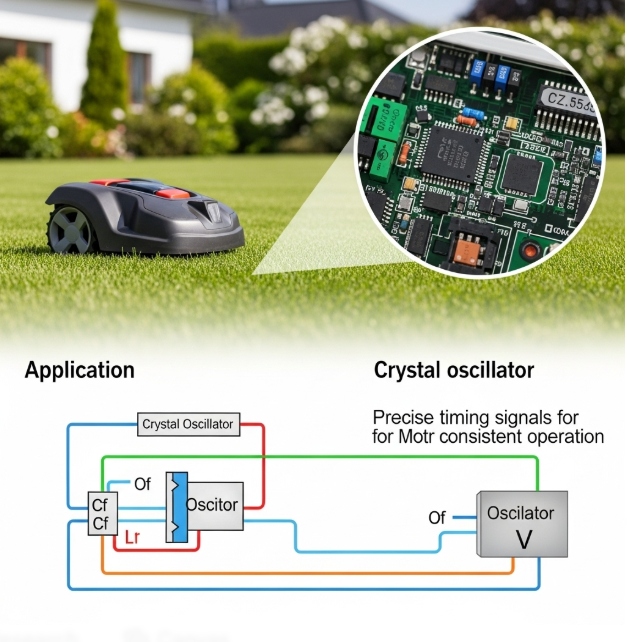

What are Crystal Oscillators Used for in Satisfactory?

In advanced smart garden systems and autonomous outdoor machinery like electric lawnmowers and robotic gardening devices, crystal oscillators play a vital yet often overlooked role. These precision components are essential for maintaining synchronized communication, reliable signal processing, and stable timing in environments where vibration, temperature fluctuations, and moisture are inevitable. In the context of industrial-grade or consumer-grade satisfactory performance for outdoor automation, the role of oscillators extends far beyond basic clock generation.

Precision Timing in Harsh Environments

Crystal oscillators serve as the timing backbone for embedded systems, microcontrollers, and wireless communication modules used in robotic lawnmowers and automated garden machines. These devices often operate under direct sunlight, in fluctuating weather, or on rough terrain, requiring clock components that can function reliably across wide temperature ranges, typically from -40°C to +85°C or even higher. Standard oscillators may drift or fail under such conditions, leading to disrupted operations, signal errors, or uncoordinated motion control.

For instance, in brushless DC motors (BLDCs) used to drive the wheels or cutting blades of smart garden robots, precise pulse-width modulation (PWM) control is necessary. This is only possible if the oscillator stability remains intact despite environmental stress.

Vibration Resistance and Mechanical Reliability

Unlike indoor electronics, outdoor robotics such as autonomous mowers are constantly exposed to mechanical shock and vibration. When cutting grass or navigating uneven terrain, vibrations can interfere with sensitive timing circuits. Vibration-resistant crystal oscillators, often constructed with ruggedized ceramic or metal packages and epoxy-sealed joints, are engineered to minimize mechanical resonance that would otherwise cause timing jitter or data corruption.

These oscillators typically follow stringent MIL-STD-202 or AEC-Q200 testing protocols to ensure operational integrity in mobile or semi-industrial systems. Their mechanical resilience contributes directly to the long-term satisfactory performance and operational lifespan of smart gardening devices.

Moisture Protection and Long-Term Reliability

Outdoor automation must also contend with high humidity, rainfall, or dew accumulation. Moisture intrusion is a silent killer for electronic circuits, especially those responsible for high-frequency signal integrity. To address this, moisture-resistant crystal oscillators with hermetic sealing or advanced conformal coatings are preferred. These protective features prevent condensation from interfering with the quartz element’s vibration or shorting internal circuits.

In embedded RF modules used for Wi-Fi, Bluetooth, or proprietary communication systems, a moisture-compromised oscillator could lead to packet loss, unstable connections, or reduced range. Therefore, environmental protection in oscillator packaging is not just a matter of durability but also a prerequisite for uninterrupted connectivity.

Synchronization in Multi-Sensor Systems

Electric gardening robots often integrate multiple sensors—ranging from ultrasonic, LIDAR, GPS, to inertial measurement units (IMUs)—for autonomous navigation and object avoidance. These modules rely on tightly synchronized signals to calculate position, detect edges, or plan efficient mowing paths. Low phase noise crystal oscillators help maintain timing consistency across these modules, enabling real-time decision-making.

Without accurate frequency sources, sensor data fusion becomes unreliable, leading to behavior such as inaccurate mapping or inefficient path tracking—negatively affecting system performance.

Energy Efficiency and Signal Stability

In battery-powered robotic garden equipment, power consumption is a critical design constraint. Low-power crystal oscillators, such as temperature-compensated (TCXO) or micro-power variants, ensure that timing functions remain stable without significantly draining the battery. These oscillators are often used in real-time clocks (RTC) and sleep-wake cycles of the main control unit, allowing intelligent power management strategies to extend operational time between charges.

Moreover, maintaining signal stability over long periods helps avoid unnecessary recalibrations or software interruptions, contributing to the overall operational satisfaction of the end-user.

Crystal oscillators used in smart gardening equipment like electric lawnmowers and autonomous garden robots must meet demanding requirements in terms of temperature tolerance, vibration resistance, and moisture protection. Their role is foundational to ensuring signal integrity, synchronization, and energy efficiency in these mobile, outdoor platforms. As garden automation becomes increasingly sophisticated, the need for robust and high-precision timing components becomes even more crucial—making crystal oscillators indispensable for achieving long-term satisfactory performance in real-world applications.

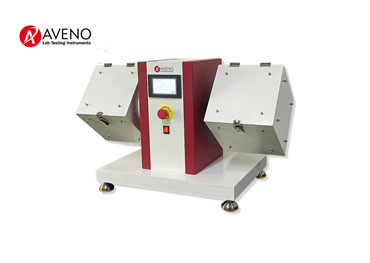

AVENO Digital Tearing Tester Upgrade

Digital tear tester is used to measure the tear strength of various woven fabrics (Elmendorf method). It can also be used to measure the tear strength of paper, plastic cloth, film, electrical tape, metal foil and other materials.

Meets the following standards:

Textiles: GB/T 3917.1 Textiles - Tear properties of fabrics - Part 1 Determination of tear strength by impact pendulum method

ASTM D 1424, DIN 53862, ISO 13937-1, ISO 4674-2, ISO 9290, etc.

AVENO R&D department continuously studies the equipment and combines the customer experience to upgrade the Digital Elmendorf Tearing Tester:

Old Model Digital Tearing Tester New Model Digital Tearing Tester

Fabric Tearing Testing machine Features:

1. Color touch screen control system, Chinese and English operation interface, built-in thermal printer, print data reports.

2. Advanced calculation method (potential energy method calculation) to ensure accurate testing and good repeatability.

3. All data and statistical results can be freely checked in the host.

4. Pneumatic sample clamping and pendulum release to ensure consistent clamping force and reduce operation steps.

5. Automatic sample cutting to reduce operation steps.

6. The test unit can be selected and automatically converted between N, gf, cN, kgf, mN and lbf to meet different standard requirements.

7. USB interface, professional computer analysis software, computer data storage (obtained national software copyright registration certificate).

8. Equipped with automatic correction function of pendulum friction damping to improve measurement accuracy.

AVENO recommended product:

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

The "quality guardian" of the textile industry ICI Mace Snag Tester

In the textile industry, fabric quality is of vital importance, so fabric testing requires the assistance of a series of testing instruments. As a professional testing instrument, ICI Mace Snag Tester has gradually become a powerful assistant for many textile companies and laboratories.

What is the Mace Snagging Tester?

The ICI Mace Snag Tester is an instrument designed to determine the tendency of fabrics to snag during normal wear. It is suitable for woven and knitted fabrics made of textured yarn, non-textured yarn, spun yarn, etc. It evaluates the anti-snagging performance of fabrics by simulating the snag conditions that fabrics may encounter in actual use.

Working principle and structure

The working principle of ICI Mace Snag Tester is to place a nail hammer suspended by a chain around the guide rod and put it on the surface of the sample on the rotating drum. After the rotating drum rotates a certain number of times at a constant speed, the sample is removed and rated against the rating chart in the rating box. The degree of snagging is evaluated according to the visual rating standard from level 5 (no obvious snagging) to level 1 (severe snagging).

Standards

China ICI Snagging Equipment complies with many international and domestic standards, such as ASTM D3939, GB/T 11047, JIS L1058, etc.

Advantages and Features

• Efficient multi-station design: 2, 4 or customized stations can be set according to needs, and multiple samples can be tested at the same time, which greatly improves the test efficiency, saves time and labor costs, and is very suitable for large-scale production enterprises and professional testing laboratories.

• Accurate simulation of real wearing conditions: It can accurately simulate the snagging scenes that fabrics may encounter during daily wear and use, making the test results closer to actual use and helping companies accurately evaluate the quality and durability of products.

• Easy to operate: The operation of the instrument is relatively simple, and the interface design is friendly, which is easy for users and even novices to use.

• Wide applicability: It is suitable for all kinds of woven and knitted fabrics, whether it is made of textured yarn, non-textured yarn or staple yarn, it can perform effective snagging tests.

ICI Mace Snag Tester is an important testing instrument in the textile industry, providing reliable fabric snagging testing solutions for textile enterprises and laboratories. It not only helps enterprises improve product quality and enhance market competitiveness, but also provides consumers with better quality and more durable textile products.

AVENO recommended product:

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com

Unveiling the Mystery of the ICI Pilling and Snagging Tester

In the textile industry, product quality is the foundation of an enterprise. When consumers buy textiles, in addition to paying attention to style and color, their trust in quality mainly depends on the durability and appearance retention of the product. Some clothes will pill after being worn a few times, while some will not lose their shape even after being worn for several years. Therefore, pilling can be said to be the "appearance killer" of textiles. Pilling is one of the important factors affecting the quality and appearance of textiles. The ICI pilling tester can help companies control the pilling performance of textiles.

1. What is the ICI Pilling Tester?

The ICI Pilling Tester is a test device that is specialized in evaluating the pilling and fuzzing properties of textiles by simulating the external forces such as friction and rubbing that textiles are subjected to during actual use.

2. Wide range of applications

ICI pilling tester has a very wide range of applications, covering all kinds of textile products, such as textiles, clothing, furniture fabrics, etc., which have certain requirements for pilling performance. ICI pilling tester can provide strong support for their quality control.

3. Aveno's ICI Pilling and Snagging Test Equipment is easy to operate and can observe data intuitively:

- Convenient operation: ICI pilling tester uses a convenient test method, which greatly shortens the test time and improves the test efficiency. Under the premise of ensuring the accuracy of the test, it can quickly complete the test of a large number of samples, helping enterprises to grasp the product quality in time and speed up the production progress.

- Intuitive and accurate data: The instrument can intuitively present parameter settings and test data on the screen interface, so that testers and enterprises can clearly understand the pilling degree of the fabric.

ICI Pilling tester for Fabric can help enterprises control product quality, help enterprises improve product quality, enhance consumers' trust in enterprises, and also protect consumers' rights and interests, so that consumers can buy high-quality textiles that meet standards. Therefore, for textile manufacturers, having a reliable and easy-to-operate ICI Pilling Tester is undoubtedly an important guarantee to gain an advantage in the fierce market competition.

AVENO recommended product:

Any demand can be referred to us!

Sales Dept Tel: +86 15280858852

Email: sales@avenotester.com

Skype: sales@avenotester.com

Web: www.avenotester.com