Choosing the right forged wheels isn’t just about style—it’s about matching your car’s specs, performance needs, and driving habits. With options like T6061-T6 one piece forged wheels and two piece forged wheels,even three piece forged wheel. It’s easy to feel stuck. But breaking down key factors helps you find wheels that look great and boost safety and performance. Let’s walk through the essential steps to get the perfect fit.

First, check your car’s basic specs. Every vehicle has strict requirements for wheel size, bolt pattern, offset, and load capacity—ignoring these causes poor fitment, damage, or safety risks. For a compact SUV, 20 inch wheels with a 6x139.7 bolt pattern mean 20 inch 6 holes forged wheels could be ideal. Find details like diameter (20inch), width (7J/8J), bolt pattern (holes x distance), offset (ET value), and load capacity in your owner’s manual or online. These numbers are non-negotiable—your wheels must match them.

3D design for customer double check the required size

Next, align with your driving style. Daily commuters prioritizing comfort? T6061-T6 forged wheels balance strength, lightness, and affordability—their heat-treated alloy resists bending, perfect for daily drives. Racing or high-performance fans? one-piece forged wheels are lighter and stiffer, cutting unsprung weight for better acceleration, braking, and cornering. Want custom style with easy upkeep? Two-piece forged wheels offer design flexibility without losing much performance.

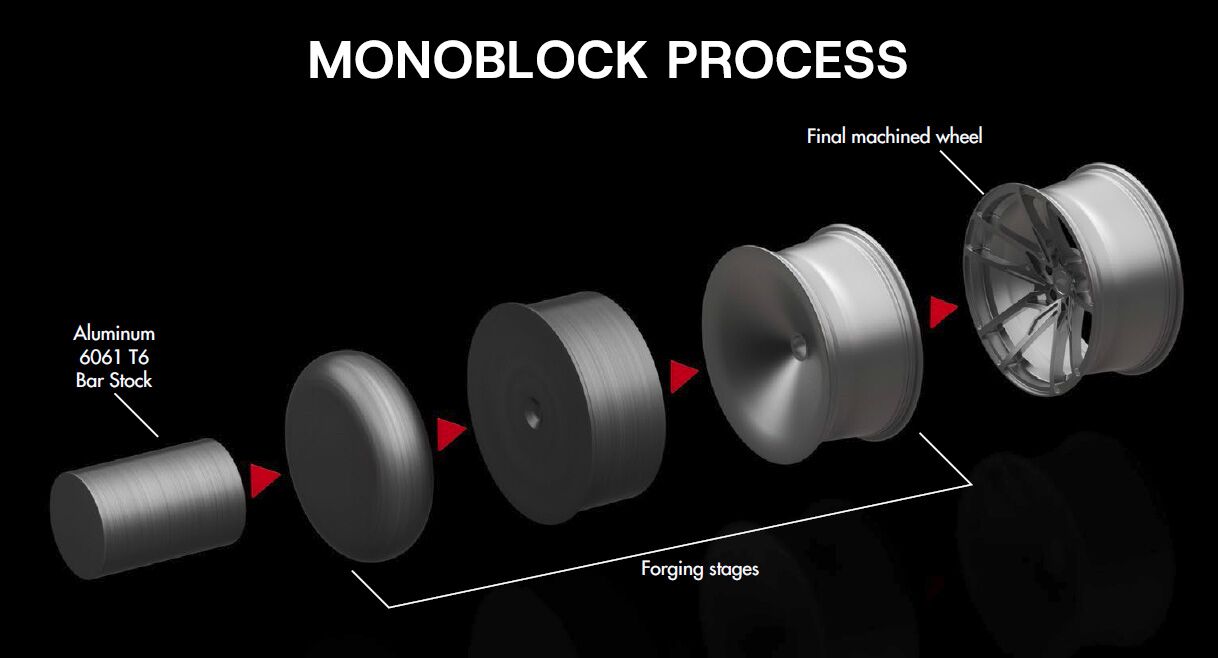

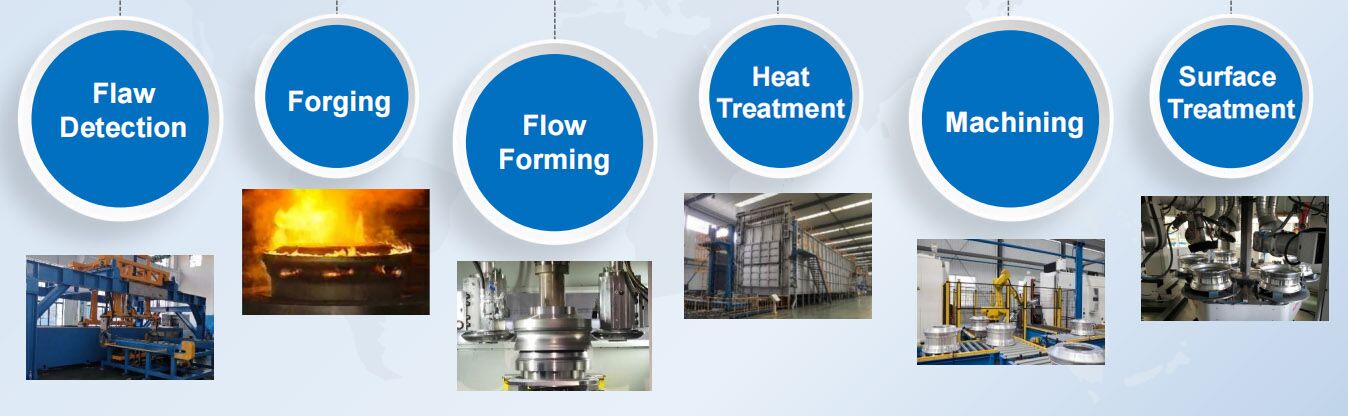

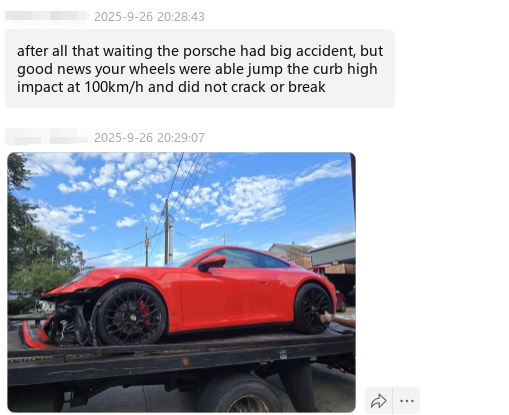

Don’t skimp on material and quality. Cheap knockoffs lack the strength of genuine forged wheels. Stick to reputable brands using 6061 aluminum alloy. Perfect aluminum alloy forged wheels from trusted suppliers save money for bulk buys, but verify manufacturing—look for rotary forging (uniform grain = more strength) and certifications like JWL/VIA. A well-made forged wheel lasts years, even in harsh conditions—quality now saves money later.

Aesthetics matter, but function first. Forged wheels come in sleek minimalist or bold intricate designs. Luxury sedans shine with polished/powder-coated wheels with clean lines; off-road trucks need larger, rugged wheels for bigger tires and traction. Complex designs are harder to clean—simpler styles are easier. Pick a finish matching your car: matte black, silver, gunmetal work for most, or go custom to stand out.

Finally, ask a pro if unsure. New to wheel upgrades or have a unique car? Visit a tire shop or forged wheel specialist—they’ll verify specs, recommend options, and test-fit for alignment. Some offer custom forging for specific needs. Choosing forged wheels is an investment—research and pro advice ensure you get it right.

In short, choosing forged wheels means balancing specs, performance, quality, and style. Start with your car’s requirements, match to your driving habits, prioritize quality materials, pick a complementary design, and ask for help.

When you choose 6061-T6 forged wheels, the goal is a perfect fit that boosts your drive. The right wheels improve performance and add personal style that makes your car stand out.

Customize color for your forged wheel