What is 4+1 bridge saw ? All-in-one versatility, empowering complex machining

The 4+1 stone bridge saw transcends mere numerical addition; it embodies the equipment's core technological philosophy.4 axis linkage enables precise coordinated movement across multiple directions, ensuring limitless cutting path possibilities. The independent milling cutter head transforms it into a multifunctional machining centre, surpassing conventional 3 axis bridge saws.

Core Advantages: Why is it your factory's preferred upgrade?

1. Intelligent CNC operating system with modular parametric input. Simply set basic parameters like edge length and angle; the system automatically plans the path without programming, ensuring straightforward operation.

2. Key core control components utilise international first-tier brands, guaranteeing stable performance and extended lifespan.

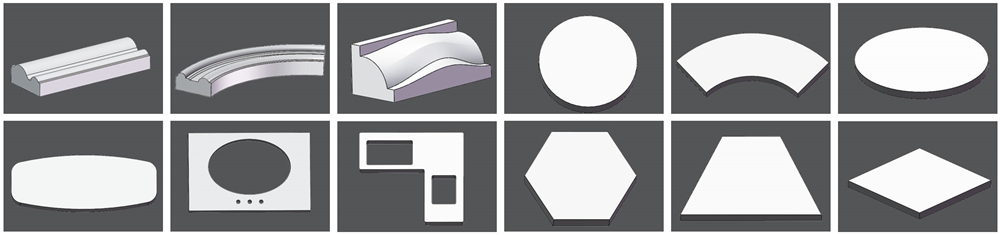

3. Capable of machining complex irregular surfaces with robust milling functions including slotting, drilling, and profiling. Effortlessly drills and mills holes for countertop, inset, and undermount basin installations, meeting diverse modern kitchen and bathroom design requirements.

4. This 4+1 cnc bridge saw accommodates blade diameters of 350-450mm with a maximum cutting thickness of 100mm.

5. Optional industrial camera allows users to select patterns from system presets, configure parameters such as side length and angle, and plan cutting paths, significantly reducing design time.

6. Equipped with suction cups for automated feeding and thickness measurement devices to ensure consistent cutting depth, supporting intelligent production.

Haineng 4+1 CNC Bridge Saw is the ideal choice for users seeking advanced processing capabilities, including custom cutting factories, stone decoration companies, and high-end kitchen and bathroom stone fabricators. It effectively resolves industry challenges such as complex shape processing difficulties, inefficient hole and groove cutting, and unstable precision control. Upgrade your production line today and let the Haineng 4+1 Stone Bridge Saw become your factory's capable partner!