You see that screw type compressor chillers are different because of their rotary screw design. These chillers use helical screws that fit together to compress fluid. This design helps the chiller run quietly and stay small in size. When there are two compressors, they share the work. This makes the chiller use less energy and work better. You get high efficiency and fewer moving parts. This means there is less damage and it is easier to fix. There are no suction or discharge valves, so there is less pressure drop. This makes the chiller work better in factories.

Key Takeaways

-

Screw type compressor chillers work well in big spaces. They are good for factories and large buildings.

-

Scroll chillers are quiet and easy to use. They fit small offices and shops with less cooling needed.

-

Centrifugal chillers are best for very big buildings. They give lots of cooling and save energy. But they need more care and fixing.

-

Reciprocating chillers are good for small jobs. They have more moving parts, so they need more repairs.

-

When picking a chiller, think about your building size. Also think about how much cooling you need. Remember to check energy and repair costs over time.

Compressor Types

When you look at HVAC systems, you see different compressor types. The compressor is very important. It pushes refrigerant gas together. This makes the gas hotter and increases its pressure. This step helps cool buildings and factories.

Screw Type Compressor Chiller

Screw type compressor chillers have two helical screws. The screws turn together. They work quietly and smoothly. There are not many moving parts. This design makes it easy to control how much cooling you need. You often find screw type compressor chillers in big buildings. They also work in factories. These chillers handle heavy jobs. They can run for a long time without problems.

Tip: Screw type compressor chillers are good for cooling large spaces.

Scroll Chiller

Scroll chillers use scroll-shaped parts. These parts move in circles to push the refrigerant. Scroll chillers are small and quiet. They fit well in offices or shops. These chillers do not cool very large spaces. But they work well for small needs.

-

Scroll chillers are simple to put in.

-

They do not cost much to keep working.

Centrifugal Chiller

Centrifugal chillers use a spinning impeller. The impeller moves refrigerant very fast. This compressor works best in big buildings. Centrifugal chillers can cool large spaces. They are very efficient. You see them in hospitals and malls. These chillers need regular check-ups. They work very well.

Note: Centrifugal chillers often use water to cool. Water helps remove heat quickly.

Reciprocating Chiller

Reciprocating chillers use pistons. The pistons move up and down. They push the refrigerant together. You find these chillers in older systems. They are also in small buildings. Reciprocating chillers have more moving parts. You may need to fix them more often. They are not as efficient as other chillers. But they work for small jobs.

You can pick air-cooled or water-cooled chillers. Air-cooled chillers use air to take away heat. Water-cooled chillers use water instead. Each compressor type is good for different needs. You should choose the right chiller for your building size and cooling needs.

Screw Type Compressor Chiller vs Scroll Chiller

Design

Screw type compressor chillers and scroll chillers work in different ways. The screw type compressor chiller has two helical rotors. These rotors spin together and squeeze the refrigerant gas. The scroll chiller uses two spiral scrolls. One scroll stays still. The other scroll moves around it. This traps and compresses the gas in small spaces.

|

Compressor Type |

Operating Principle |

|---|---|

|

Scroll Compressor |

Uses two spiral scrolls. One scroll orbits around the other, squeezing refrigerant into smaller spaces. |

|

Screw Compressor |

Uses two helical rotors. The rotors mesh together, drawing in and compressing the refrigerant. |

Scroll compressors squeeze the gas as the scrolls move. Screw compressors finish squeezing with each full turn of the rotors. Screw type compressor chillers run smoothly. They are easy to control. This makes them good for places that need strong cooling.

Efficiency

Screw type compressor chillers use energy very well. They work best in big buildings or factories. You get high efficiency when you need lots of cooling. Scroll chillers are okay for smaller spaces. They do not use energy as well as screw chillers.

|

Chiller Type |

Efficiency Rating (COP/EER) |

Capacity Range (kW) |

Economic Preference |

|---|---|---|---|

|

Scroll |

Moderate |

100 - 200 |

Can be used depending on conditions |

|

Screw |

High |

200 - 500 |

Preferred for energy efficiency |

|

Screw |

Very High |

500+ |

Only effective solution at this scale |

If you want to save money on energy in a big building, pick a screw type compressor chiller. For small jobs, a scroll chiller works fine.

Noise

Noise is important in your building. Screw type compressor chillers make more noise than scroll chillers. Small screw chillers run at about 70 to 80 dB. Large screw chillers can reach 85 to 95 dB or more. Scroll chillers have about the same sound level. Their noise is softer and blends in better.

|

Chiller Type |

Noise Level (dB) |

|---|---|

|

Small Open Screw Chiller |

70 - 80 dB |

|

Large Open Screw Chiller |

85 - 95 dB or higher |

|

Scroll Chiller |

Similar, but less tonal |

If you need a quiet place, choose a scroll chiller. Screw type compressor chillers are better where noise does not matter.

Reliability

You want your chiller to last a long time. Screw type compressor chillers have fewer moving parts than some other chillers. They are more complex than scroll chillers. Screw compressors handle heavy work and run for many hours. Scroll chillers have a simple design. They need less fixing. They work well for light and medium jobs.

Tip: Screw type compressor chillers are strong for tough jobs and long hours. Scroll chillers are easy to keep working for smaller jobs.

Cost

Cost is always something to think about. You need to look at the price to buy and keep the chiller working. For medium buildings, screw type compressor chillers cost less to buy than scroll chillers. Screw chillers need more fixing because they are more complex.

|

Chiller Type |

Initial Cost per Refrigeration Ton |

Maintenance Requirements |

|---|---|---|

|

Scroll |

800-1200 yuan |

Less frequent maintenance, simpler design |

|

Screw |

600-1000 yuan |

More maintenance, complex structure, more parts |

When you think about total cost, look at energy use and fixing costs too.

Applications

Pick your chiller based on what you need to cool. Scroll chillers are best for places with medium cooling needs. You see them in offices, data centers, and small factories. Screw type compressor chillers are better for big jobs. You find them in large buildings, factories, and district cooling systems.

|

Chiller Type |

Common Applications |

|---|---|

|

Scroll Chiller |

Commercial buildings, data centers, smaller industrial operations |

|

Screw Chiller |

Large commercial buildings, industrial plants, district cooling systems |

-

Scroll chillers work well for:

-

Offices

-

Data centers

-

Small factories

-

-

Screw chillers are best for:

-

Large office buildings

-

Factories

-

District cooling

-

Screw type compressor chillers give you more power and control for big jobs. Scroll chillers are simple and cheaper for smaller spaces.

Screw Chiller vs Centrifugal Chiller

Structure

Screw chillers and centrifugal chillers are very different. Screw chillers have two helical rotors that turn slowly. This makes the machine simple. It is easy to fix. Centrifugal chillers use a fast-spinning impeller. The impeller needs more parts to work well. You find more gears and complex systems inside.

|

Feature |

Screw Type Compressor Chillers |

Centrifugal Chillers |

|---|---|---|

|

Refrigeration Capacity |

30RT - 500RT, often multi-head for larger needs |

150RT - 3000RT, typically single compressor |

|

Structure |

Simple structure with fewer parts |

Complex structure with more parts |

|

Rotation Mechanism |

Direct low-speed rotation of rotors |

High-speed rotation of impeller via gears |

|

Maintenance |

Easier maintenance, can operate with one compressor off |

Complex maintenance, requires full shutdown |

|

Capacity Adjustment |

7.5% - 100%, continuous adjustment possible |

40% - 100%, prone to surge below 40% load |

|

Impact on Power Grid |

Smaller starting current due to multiple compressors |

Larger starting current due to single compressor |

A screw chiller is simpler. You can fix it faster. It keeps running even if one part stops. Centrifugal chillers need more care. You must shut down for repairs.

Capacity

Think about how much cooling you need. Screw chillers work best for medium and large spaces. They handle 30 to 800 tons of refrigeration. Centrifugal chillers cool very big buildings. Their capacity starts at 200 tons and goes much higher.

|

Chiller Type |

Typical Capacity Range (tons) |

|---|---|

|

Screw Type Compressors |

30 to 800 |

|

Centrifugal Chillers |

200 to thousands |

Hospitals or malls may need a centrifugal chiller. Factories or large offices can use a screw chiller.

Efficiency

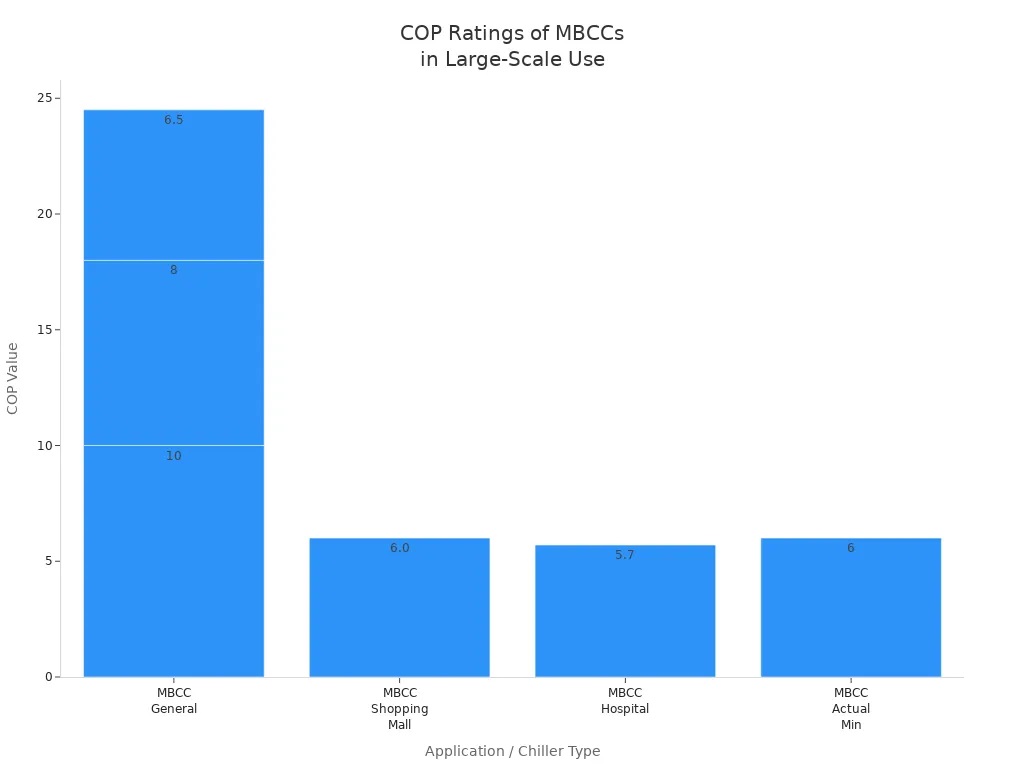

You want your chiller to save energy and money. Screw chillers give good energy efficiency for most jobs. Centrifugal chillers, especially magnetic bearing types, are even better in huge buildings. Some magnetic bearing centrifugal chillers have COP values up to 10. In shopping malls, these chillers save almost 10% more energy than older ones.

Centrifugal chillers are best for very big buildings. Screw chillers work well for most factories and offices. Always check the total cost before you choose.

Maintenance

You want a chiller that is easy to keep working. Screw chillers have fewer moving parts. You can fix one compressor while others keep running. This saves time and keeps your building cool. Centrifugal chillers need more care. You must shut down the whole system for repairs. Their fast parts wear out quicker.

Tip: Pick a screw chiller if you want easy maintenance and less downtime.

Application Suitability

Match your chiller to your building. Screw chillers fit factories and large offices. They work well where cooling needs stay steady. Centrifugal chillers are best for hospitals, malls, and district cooling systems. These chillers are used where you need very high capacity and top energy efficiency.

-

Screw chillers resist rust better. They use positive pressure systems to keep air and water out.

-

Centrifugal chillers often use negative pressure systems. These can let air in and cause rust or lower performance.

If you want a reliable chiller for a big factory, pick a screw chiller. For huge buildings or hospitals, a centrifugal chiller gives more cooling and better energy efficiency.

Screw Chiller vs Reciprocating Chiller

Design

Screw chillers and reciprocating chillers work in different ways. A screw chiller has two screws that spin together. This spinning squeezes the refrigerant. A reciprocating chiller uses pistons that move up and down. The pistons push the refrigerant into tight spaces. Screw chillers have fewer moving parts. Reciprocating chillers have more parts that can break.

|

Feature |

Screw Chiller |

Reciprocating Chiller |

|---|---|---|

|

Compressor Type |

Rotary screws |

Piston-driven mechanism |

|

Size |

Larger, needs more space |

Compact, fits in small areas |

|

Maintenance |

Lower, fewer moving parts |

Higher, more parts to check |

|

Control |

Less precise |

More precise, good for small jobs |

Performance

You want your chiller to save energy and work well. Screw chillers use less electricity in big buildings. Reciprocating chillers are better for small spaces. Screw chillers have higher COP values. This means they cool with less power.

|

Compressor Type |

Energy Efficiency (COP) |

Reliability (Lifespan) |

|---|---|---|

|

Screw Chiller |

3.5–4.0 |

20–25 years |

|

Reciprocating Chiller |

2.5–3.0 |

10–15 years |

Pick a screw chiller if you want it to last longer and use less energy.

Noise

Noise matters in your building. Screw chillers are quieter because the screws move smoothly. Reciprocating chillers make more noise. The pistons and other parts cause extra sound. Choose a screw chiller if you need quiet.

Tip: Screw chillers are good for quiet places like offices or schools.

Reliability

You want your chiller to work for many years. Screw chillers last longer because they have fewer parts to break. Reciprocating chillers need more repairs. Pistons, rings, and valves wear out faster.

|

Parameter |

Reciprocating Chiller |

Screw Chiller |

|---|---|---|

|

Typical Service Life |

15 years |

15–20 years |

|

Common Failures |

Rings, bushings, valves |

Bearings, seals |

You spend less time fixing screw chillers. This means your building has less downtime.

Cost

Think about how much your chiller will cost over time. Screw chillers cost more to buy and install. Reciprocating chillers are cheaper at first. You may pay more for repairs and energy with reciprocating chillers. Screw chillers save money because they last longer and use less energy.

|

Feature |

Screw Chiller |

Reciprocating Chiller |

|---|---|---|

|

Initial Cost |

Higher |

Lower |

|

Maintenance Cost |

Lower |

Higher |

|

Lifespan |

Longer |

Shorter |

Applications

Pick your chiller based on your building size and needs. Screw chillers are best for large factories and malls. They work well where cooling needs stay steady. Reciprocating chillers fit small offices and shops. They are good when you need precise control.

|

Chiller Type |

Key Features |

Suitable Applications |

|---|---|---|

|

Screw Chiller |

Reliable, compact |

Medium to large buildings |

|

Reciprocating Chiller |

Simple, easy to maintain |

Small offices, shops |

You can use a scroll chiller for small spaces. Centrifugal chillers work for very large buildings. Always check your cooling needs before you choose.

Choosing the Right Chiller

Capacity Needs

You need to pick a chiller that fits your building size. Big buildings often use screw chillers because they handle large loads. The table below shows how much cooling each type can give:

|

Chiller Type |

Capacity Range (KW) |

Application Type |

|---|---|---|

|

Air-Cooled |

105 KW to 928 KW |

Large-scale, one-to-one cooling |

|

Water-Cooled |

121 KW to 2154 KW |

Medium to large-scale cooling |

Small offices can use scroll chillers or reciprocating chillers. Hospitals and malls need centrifugal chillers or big screw chillers.

Reliability

You want your chiller to work well and not break often. Screw chillers last a long time. They have fewer parts that can break. You do not need to fix them much. Centrifugal chillers work well but need more fixing because they are more complex. Scroll chillers are simple and good for light jobs. Reciprocating chillers need more repairs as they get older.

Tip: Screw chillers are best for big buildings if you want them to last.

Cost

Think about how much you pay at first and over time. Water cooled chillers cost more to buy because they need pumps and heat exchangers. Air-cooled chillers are cheaper to install but use more power when it is hot. The table below shows what affects the cost:

|

Factor |

Air-Cooled Compressors |

Water-Cooled Compressors |

|---|---|---|

|

Initial Cost |

Lower |

Higher |

|

Power Demand & Energy |

Higher in hot climates |

Lower, but extra pumps |

|

Infrastructure |

Needs airflow |

Needs water supply |

|

Cost Recovery |

Limited heat recovery |

Greater heat recovery |

Look at how much energy your chiller uses and what you will spend over its life.

Maintenance

Taking care of your chiller helps it work well. For screw chillers, you should:

-

Change shaft seals if they leak.

-

Listen for strange sounds when not running full.

-

Check the pressure and temperature.

-

Test the oil to see if it is good.

-

Change the oil after many hours.

-

Clean tubes to help heat move better.

-

Treat water so pressure does not get too high.

-

Check and change compressor oil.

-

Purge machines with low pressure.

-

Watch water temperature and flow.

Scroll and reciprocating chillers are easier to take care of, but you still need to check them often.

Application Suitability

Pick a chiller that matches your building and needs.

-

Look at your system size and space.

-

See how your cooling needs change during the day.

-

Think about saving energy and helping the environment.

-

Check if you can do maintenance and what it costs.

-

Think about how much you pay now and later.

Factories do best with screw chillers or water cooled chillers. Small shops can use scroll or reciprocating chillers. Centrifugal chillers are good for hospitals and malls.

You can easily see how screw type compressor chillers are different from other chillers. Screw chillers can cool bigger spaces and are very reliable. They cost more money and need more care.

|

Feature |

Screw Type Compressors |

Other Types (e.g., Scroll) |

|---|---|---|

|

Capacity |

30 to 400+ tons |

2 to 140 tons |

|

Reliability |

High |

Varies |

|

Cost |

Generally higher |

Generally lower |

|

Maintenance |

Moderate to high |

Generally lower |

Here are some things to think about when picking a chiller:

-

Find out how much cooling your building needs at its busiest time.

-

Make sure you have enough room to put in and fix the chiller.

-

Think about if your building might get bigger or need backup cooling.

Screw chillers are best for big buildings and factories. Scroll and reciprocating chillers are good for small places. Centrifugal chillers work well where you need steady and strong cooling. Do not choose a chiller that is too small or forget about future costs.