In today's competitive manufacturing market, efficient cooling solutions have become the goal pursued by industrial manufacturing companies in all walks of life. As a leading supplier, OUMAL Refrigeration Machinery Co.,Ltd . has developed water chiller cooling system and 30 ton air cooled screw chiller to meet customer needs, bringing a new turn to the manufacturing industry.

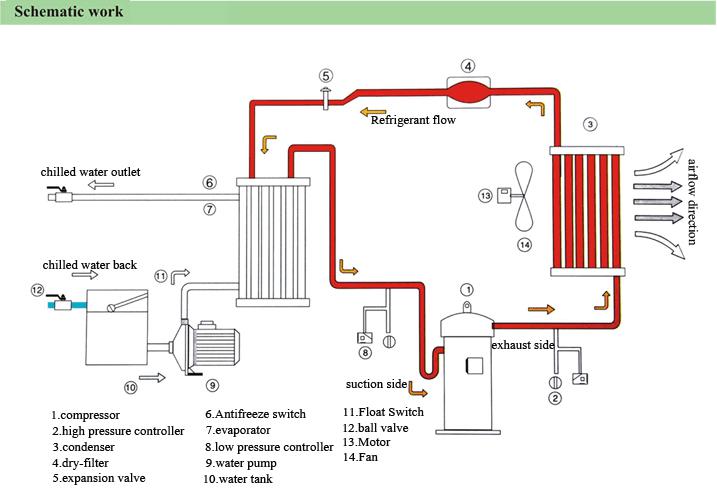

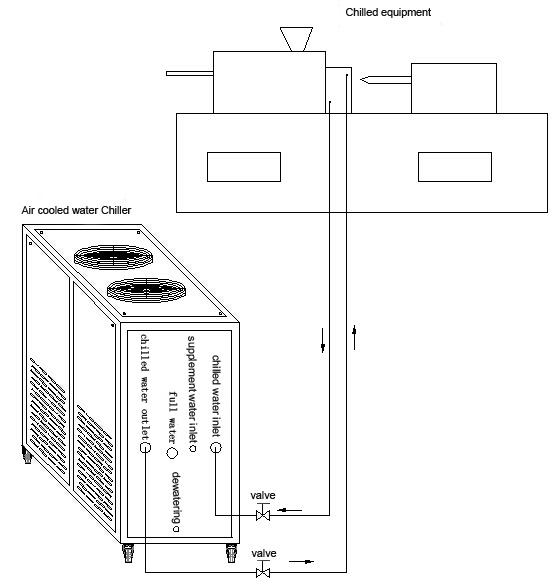

The water chiller cooling system is an excellent process cooling solution that provides efficient and reliable cooling effects by utilizing the sensible heat transfer characteristics of water. The water cooling system mainly uses advanced technology and sophisticated control devices to provide accurate and stable process temperature control for manufacturing processes in different industries. Whether it is injection molding, thermoforming, blown film or plastic extrusion, compound mixing and other processes, our water cooling system can effectively improve product quality and shorten manufacturing time.

On the other hand, our 30 ton air cooled screw chiller is an innovative product that has attracted much attention in the industry. The equipment enjoys a high reputation for its excellent cooling effect and high energy-efficient operation. Using air-cooling technology, the chiller eliminates the reliance on external water sources, providing manufacturers with greater flexibility and convenience. Whether it is a large-scale production environment or an application scenario with special requirements, the 30 ton air cooled screw chiller can give full play to its advantages, ensuring efficient cooling and energy-saving operation.

With years of industry experience and expertise, OUMAL Refrigeration Machinery Co.,Ltd .continues to improve the performance and reliability of our water chiller cooling system and 30 ton air cooled screw chiller. At the same time, we also focus on user experience, simplify the operating interface, and make installation and maintenance more convenient. Whether it is a new project or upgrading existing equipment, we are committed to meeting customer needs and providing reliable solutions.

Choose OUMAL Refrigeration Machinery Co.,Ltd , you will get excellent products and quality services.