In the wave of intelligent transformation in the cement industry, the "last mile" of the shipping process has always been a pain point for many companies. Low efficiency of manual loading, severe dust pollution, reliance on manual labor for high-sided trucks, and chaotic vehicle dispatching management... these problems not only drive up operating costs but also become bottlenecks restricting enterprise development. Today, Xiamen Gachn presents the world's first "in-cargo" intelligent cement loading machine, which, with its revolutionary design and superior performance, is bringing a profound revolution to the industry.

Saying Goodbye to Industry Maladies: Three Major Pain Points of Traditional Loading Modes

For a long time, neither traditional robotic arm solutions nor early palletizing solutions have fundamentally solved the core problems of cement loading.

Efficiency Bottleneck: The actual effective loading efficiency of most traditional equipment hovers around 70-80 tons/hour, and its poor stability makes it difficult to match the capacity of modern cement packaging lines, becoming a key weakness restricting overall production efficiency.

Adaptability Limitations: Faced with the large number of high-sided freight vehicles in the market, traditional equipment is often "helpless," forcing automated loading lines to be interrupted, requiring manual intervention, and rendering intelligent systems useless. Environmental and Operational Pressures: High-level bag throwing or dropping generates massive amounts of dust, creating immense environmental pressure; the complex centralized structure leads to high failure rates, cramped maintenance space, and persistently high maintenance costs and downtime losses.

Key to the Solution: What is "In-Cargo (ICO)" Intelligent Loading?

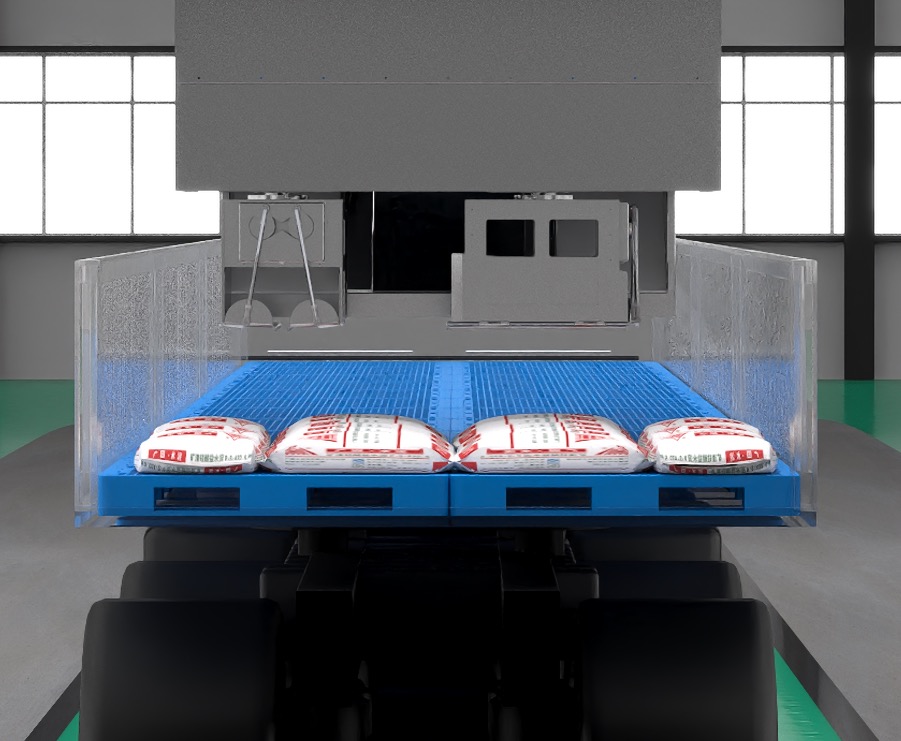

The core of GIGABYTE's solution lies in its "In-Cargo" design concept. Unlike all traditional equipment that operates outside the truck bed, our intelligent loading machine innovatively extends the bag-stacking head directly into the truck bed for operation.

This fundamental change is like transforming "surgery" from an external operation to a minimally invasive intervention, resulting in a comprehensive leap in performance:

Eradicating Dust: With the bag-stacking head positioned low, the height difference between the cement bags and the truck bed floor is minimized, significantly suppressing dust generation at its physical source.

Conquering All Vehicle Models: Whether for low-sided or high-sided trucks, the machine head can easily operate deep inside the truck bed, achieving true seamless adaptation to all vehicle models and breaking down vehicle model barriers in automated loading.

More Stable Operation: The compact and direct operating method reduces long-distance, wide-range swinging of the robotic arm, resulting in smoother operation and a significantly lower failure rate.

Superior Performance Parameters, Setting a New Industry Benchmark

Our "in-carriage" intelligent loading machine not only boasts an advanced concept but also solid performance data supporting its outstanding performance:

Highly Efficient Output: The system's loading efficiency is perfectly matched with the packaging machine, stably achieving a high output of 90-100 tons/hour, fully releasing shipping capacity.

Precise and Fast: The packaging capacity reaches up to 120 tons/hour, and the packing speed reaches 40 packs/minute. Vehicle parking deviation is allowed to be ±120mm. Through a 3D LiDAR scanning system and a linear laser guide line, the system can intelligently guide and adapt, greatly reducing the precision requirements for driver parking and improving overall flow efficiency.

Flexible and Intelligent: Supports horizontal, vertical, and mixed palletizing modes. Through its independently developed JNGGZC-001-11 intelligent control and management system (based on the Schneider motion servo platform), it automatically calculates the optimal palletizing scheme based on vehicle type and tonnage, ensuring neat stacking and high space utilization.

Core Configuration for a Reliable Foundation: Top-tier performance stems from uncompromising commitment to core components:

Intelligent Brain: Employs a Schneider integrated control platform and servo drive system, ensuring precise control, rapid response, and reliable operation.

Sharp Eyes: A 3D LiDAR scanning system constructs a real-time 3D model of the vehicle, accurately identifying size, location, and foreign objects, providing a high-definition "vision" for intelligent decision-making.

Robust Limbs: Key power components such as the walking and lifting motors use Schneider brand products, ensuring power and stability under long-term high-load operation.

Safety Assurance: The entire machine is designed to meet stringent safety standards, with safety sensors and protection at key locations, and equipped with comprehensive pneumatic and dust removal interfaces.

Creating Comprehensive Customer Value

Choosing Gachn's "Box-Type" Intelligent Loading Machine will bring you value far exceeding the equipment itself:

Significant Economic Benefits: Increases shipping efficiency by over 30%, reduces loading manpower by 2-3 people per shift, and significantly reduces environmental treatment costs and maintenance downtime losses caused by dust.

Comprehensive Management Upgrade: Achieves unmanned, standardized loading, automates vehicle-cargo matching and data statistics, and seamlessly integrates with ERP/MES systems, driving the factory towards digital and intelligent management.

Social and Environmentally Friendly: Greatly improves the working environment for workers, significantly reduces fugitive emissions in the plant area, and helps enterprises achieve green and sustainable development goals.

Looking to the Future: Making Intelligent Loading a Core Competency

In the grand context of "Industry 4.0" and "Smart Manufacturing," intelligent back-end production is also a key element in building a company's core competitiveness. Gachn's world's first "Box-Type" intelligent cement loading machine is not only an advanced piece of equipment, but also a strategic fulcrum for building an efficient, clean, and intelligent modern cement plant.

We cordially invite you to delve deeper into this revolutionary solution and explore together how it can create tangible benefits for your business.

Take action now to schedule a private online demo or obtain a detailed technical solution.