10 HP process chillers are special in metal finishing. They give very accurate temperature control and work well every time. Good chillers help keep metal finishing steady. This stops cracks, warping, and other problems. Studies show that controlling temperature makes metal harder and stronger. It also helps the metal bend without breaking. It uses less energy and saves money too. A good industrial process chiller keeps the workplace the same all the time. This makes every finished product better and more exact. Companies use these chillers for tough jobs and to work fast.

Key Takeaways

-

10 HP process chillers keep metal finishing cool and steady. This stops cracks, warping, and weak metal from happening. These chillers have strong parts like stainless steel tanks and copper coils. These parts help them last a long time and work well. Microcomputer controls keep the temperature just right. This makes products better and saves energy. They do not need much maintenance. They have safety features to protect machines and stop breakdowns. 10 HP chillers are flexible and save energy. They are easy to move and good for many metal finishing jobs.

10 HP Chiller Features

A process chiller is a machine that cools things down in factories. The OUMAL OMC-10A 10 HP chiller is great for metal finishing. It uses air-to-water cooling and has a copper coil that is strong. The tank is made of stainless steel, so it does not rust and keeps water clean. Workers can use the microcomputer control panel to set and check the temperature. This chiller keeps the temperature steady, which is very important for metal finishing.

Note: The OMC-10A model uses good parts like Schneider electrical components. These parts help the chiller stay safe and work well.

The table below lists the main features of 10 HP process chillers used for metal finishing:

|

Feature Category |

Details / Examples |

|---|---|

|

Compressor |

Air-cooled scroll compressors (Copeland, Panasonic) |

|

Refrigerants |

R22, R407C, R134A, R404A |

|

Heat Exchanger / Tank |

Stainless steel water tanks, shell and tube heat exchangers |

|

Water Pump |

Durable, corrosion-resistant pumps |

|

Electrical Components |

Schneider for stability and safety |

|

Safety Devices |

Overheat, high/low pressure, phase protection, anti-freeze |

|

Condenser Type |

Air-cooled finned condensers |

|

Temperature Control |

Microcomputer control, precise regulation |

|

Portability |

Casters for mobility |

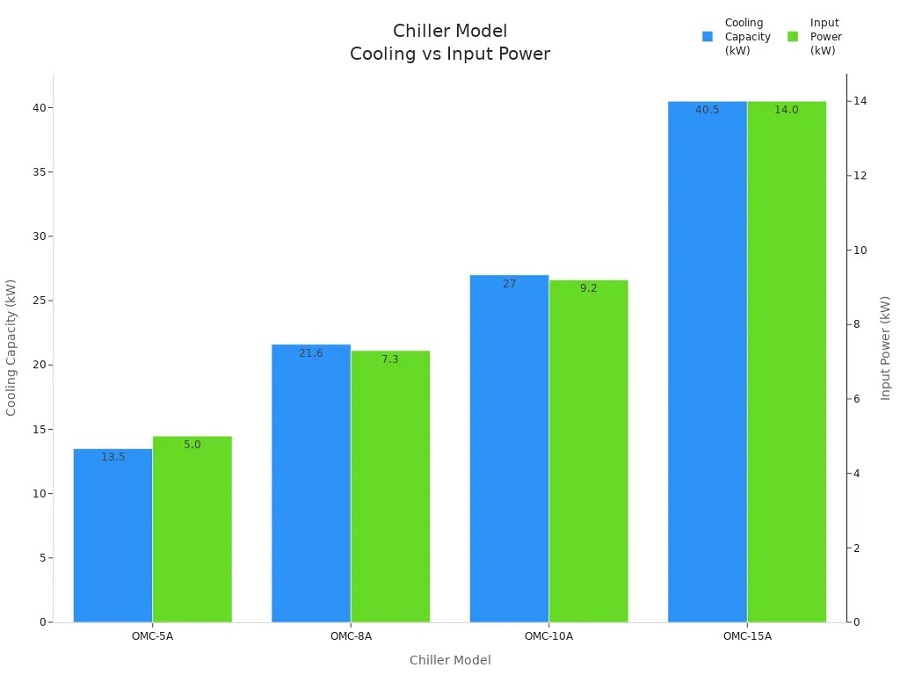

Copper coils and stainless steel tanks help the chiller last a long time. These materials stop rust and keep the chiller working well. The OMC-10A chiller can cool with 27 kW (7.7 tons), which fits many metal finishing jobs. It uses about 9.2 kW of power, so it is good for saving energy and cooling.

How Process Chillers Work

Process chillers use a simple cycle to cool things down. First, the refrigerant goes into the evaporator. It takes heat from the process fluid, like the liquid used in metal finishing. The refrigerant turns into a gas. The compressor pushes this gas to a higher pressure and temperature. Then, the gas goes to the condenser. In air-cooled chillers, the condenser lets out the heat into the air, and the gas turns back into a liquid. The liquid goes through an expansion valve, which makes it cooler and lowers the pressure. The cycle starts again.

-

The refrigerant takes heat from the process fluid in the evaporator.

-

The compressor makes the refrigerant gas hotter and under more pressure.

-

The condenser lets out heat to the air, turning the gas into a liquid.

-

The expansion valve cools the liquid, and the cycle repeats.

Microcomputer controls help keep the temperature steady. They let the chiller keep the water temperature close to the same, usually within ±1°C. This is important for process chillers in metal finishing. The OMC-10A chiller uses these controls to keep things safe and make sure the results are good.

Metal Finishing Cooling Needs

Temperature Control Challenges

Keeping things cool is very important in metal finishing. Jobs like anodizing, plating, and quenching need steady temperatures. If the temperature changes a lot, metal can bend or break. It might also get weaker. Workers have some problems when they try to keep the right temperature:

-

Some materials, like plastics or MDF panels, can bubble or crack if they get too hot.

-

Certain parts must stay within a set temperature. If it gets too hot, these parts can bend or break.

-

Some parts, like refrigerant compressors, need careful heating and cooling.

-

Metal parts with different thicknesses can heat up unevenly. This makes it hard to keep the whole part at the right temperature.

-

Big, heavy parts need more heat to process. This can slow down work and cost more money.

A chiller helps by keeping the temperature steady. The 10 HP chiller uses sensors to check for temperature changes during busy times. If the temperature goes up, the chiller sends coolant through heat exchangers to cool things down. When the temperature is right, the system stops sending coolant. This automatic control keeps everything safe and working well.

Application Examples

Keeping the temperature steady helps protect products and machines. Here are some ways bad temperature control can hurt metal finishing:

-

If the temperature changes, metal can get bigger or smaller. This can cause size mistakes.

-

High heat can change the metal’s surface or inside. The metal can get softer or weaker.

-

Too much heat can burn or discolor the metal. It can also cause other surface problems.

-

Hot conditions can wear out tools faster. Grinding wheels can get damaged too.

-

Bad temperature control can leave stress in the metal. This can make it bend or break later.

A 10 HP chiller gives the cooling needed to stop these problems. By keeping the temperature in a small range, the chiller helps each job go well. This means better products, less stopping, and longer machine life. Good chillers also help make more products. They help every finished product meet high standards.

Benefits of 10 HP Chillers

Efficiency and Reliability

10 HP chillers save energy and work well in metal finishing. They have special compressors that change speed when needed. This helps keep the temperature steady and uses less energy. Many factories say their energy use drops a lot after using these chillers. The system now uses only about one-third of the energy older chillers used. The pumps also use less power, so more energy is saved.

Factories have fewer problems because the chiller keeps water temperature and pressure steady. This helps protect machines and makes products better.

Chillers with variable-speed compressors do not turn on and off too quickly. This means less stress on the compressor and it lasts longer. Electronic safety features help stop problems before they happen. Soft-start controls help the system start gently and protect the parts. These things make the chiller good for busy factories.

These chillers are small and fit well in crowded places. Wheels make it easy to move them around. The system uses closed water loops, so the water stays clean and needs less care.

Key reliability features include:

-

Steady temperature for better results

-

Fewer breakdowns because of safety features

-

Less waiting because setup is fast and easy

-

Energy-saving choices that cost less to run

Low Maintenance

10 HP chillers need less care than old ones. Most need a check-up once a year. This means checking oil, cleaning coils, and looking at wires. Trained workers should look for leaks and test safety parts. You do not need to change the oil often, but checking it helps keep the compressor healthy.

Typical maintenance steps:

-

Do all weekly and monthly checks during the yearly service.

-

Check the oil for water and acid.

-

Look at and tighten all wires.

-

Clean and paint any rusty spots.

-

Clean air filters and coils.

New chillers use safe refrigerants that last longer. Better motors and coils help stop breakdowns. Chillers that are the right size do not have as many problems. This means less fixing and less time when the chiller is not working.

Many factories say they spend 80% less time on maintenance with new chillers. They also need outside help much less. Having spare parts and regular checks helps stop long waits for repairs.

Safety features keep the chiller and factory safe. Some of these are:

-

Protection from too much electric current

-

Switches for high and low pressure

-

Timers for safety delays

-

Power phase protection

-

Anti-freeze protection

These features help the chiller work well and stop big problems. This means the system is efficient, works well, and lasts a long time for metal finishing.

Industrial Process Chiller Comparison

10 HP vs. Other Capacities

Picking the right process chiller depends on what the factory needs. A 10 HP chiller gives good cooling and saves energy. Smaller chillers, like 3 HP or 5 HP, are for easy jobs or small tanks. They use less power but can’t cool big jobs. Bigger chillers, like 20 HP or 30 HP, cool more and fit large factories. These are best when many machines run at once.

A 10 HP chiller is good for medium or big metal finishing work. It cools enough for jobs like anodizing, plating, and quenching. This size works well without wasting energy. Many companies pick 10 HP chillers because they are flexible. They can cool more than one machine or tank at the same time. This makes them a smart pick for businesses that want to grow.

Tip: You can change some parts to fit your job. Pick different refrigerants, evaporators, or power supplies. Stainless steel tanks and pumps stop rust and last longer. Touch screens and safety features make it easy and safe to use.

Air to Water vs. Other Types

Factories can choose air-to-water, air-to-air, or water-to-water chillers. Each type works best for certain jobs. The table below shows how air-cooled and water-cooled chillers are different:

|

Feature |

Air-Cooled (Air-to-Air) |

Water-Cooled (Water-to-Water) |

|---|---|---|

|

Cooling Power |

Lower, changes with air temp |

Higher, steady in all weather |

|

Energy Efficiency |

0.8–1.2 kW/ton |

0.45–0.64 kW/ton |

|

Lifespan |

15–20 years |

20–30 years |

|

Maintenance |

Easy, not needed often |

Needs water checks, more work |

|

Installation |

Small, easy to move |

Needs cooling tower, more space |

|

Performance |

Drops in hot weather |

Stays strong in high heat |

Air-to-water chillers use air around them to cool down. They are simple to set up and move. These chillers work best in places that are not too hot. Water-cooled chillers use water from a cooling tower. They cool better and save more energy, even when it is hot outside. Their cooling stays the same even if the weather gets warmer.

Factories can add special features to chillers for their needs. Some options are titanium tube evaporators, very low temperature settings, and smart controls. These help the chiller work for any metal finishing job and keep the system running well.

10 HP process chillers are special in metal finishing for many reasons.

-

They use scroll compressors and eco-friendly refrigerants to save energy. These parts also help the environment.

-

The air-cooled design uses aluminum fin condensers. This gives strong cooling and does not need extra water systems.

-

Stainless steel tanks and good temperature controls keep things safe and steady.

-

These chillers work for many jobs, like anodizing and die casting. They are easy to set up and do not need much care.

Experts say it is best to pick chillers that fit your cooling needs. They should have good parts and strong support after you buy them. Companies that choose the right chiller get better products. Their machines last longer and work better.

FAQ

What makes a 10 HP process chiller ideal for metal finishing?

A 10 HP process chiller gives strong cooling for metal finishing. It keeps the temperature steady so metal does not get ruined. This helps stop mistakes and keeps machines safe. Many factories pick this size because it is powerful and saves energy.

How does the OUMAL OMC-10A chiller ensure temperature stability?

The OUMAL OMC-10A has a microcomputer control panel. This panel checks the temperature and changes it fast. It keeps the water temperature close to the same, between ±0.5°C and ±2°C.

Can a 10 HP chiller handle multiple metal finishing machines?

A 10 HP chiller can cool more than one machine or tank. Its strong cooling helps with many metal finishing jobs. Many companies use one chiller for several tasks at once.

What safety features do 10 HP process chillers include?

These chillers have safety features to stop problems. They protect the compressor from getting too hot. They also have over-current and phase protection. These features help keep the chiller safe and working well.

Are 10 HP process chillers easy to move and install?

Most 10 HP chillers are small and have wheels. Workers can move them without trouble. The setup is easy, so it does not take long to install.