In the plastic woven valve bag production workshop, there used to be the tedious and inefficient manual bag picking - workers stared at the bags on the assembly line day after day, trying to find holes, joints or bottom sticker deviation defects from the fast-moving cloth rolls, but fatigue always led to missed inspections, and high labor costs and unstable product quality became stumbling blocks to the development of enterprises. Today, the emergence of Gachn AI visual inspection system is bringing disruptive changes to this traditional industry with its "eagle eyes and golden eyes" precision and efficiency.

Why must plastic woven valve bag companies embrace AI visual inspection?

The pain points of the traditional production model have long become an industry consensus. Raw material cloth rolls often have problems such as scratches, holes, and deviations of the warp and weft lines. Manual bag picking not only requires 4-5 workers per production line, but also is affected by emotions and fatigue, and the missed inspection rate remains high, resulting in an excessive scrap rate of finished bags. What's more difficult is that the current situation of difficulty in recruiting workers and rising labor costs year by year has put companies in a dilemma of "wanting to expand production but not being able to support workers."

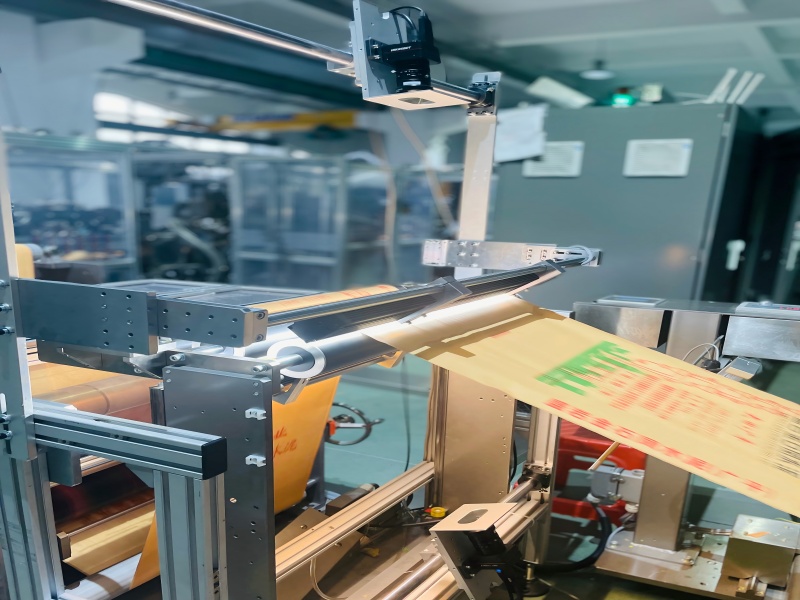

The birth of the Gachn AI visual inspection system is precisely to solve these problems. As the core technological achievement of Gachn Jeenar this system realizes the full process intelligence from raw material detection to finished bag defect recognition through the combination of high-definition cameras and deep learning algorithms.

Gachn AI visual inspection system: more than "seeing", more about "understanding"

Understanding ordinary visual equipment,Gachn AI visual inspection system , has real "intelligent judgment" capabilities. It can accurately capture two types of key defects:

Raw material defects: including holes, joints, warp and weft offsets, abnormal scratches, etc. in the cloth roll, blocking the generation of waste from the source;

Bag making process defects: such as skewed corners of finished bags, no bottom stickers, bottom sticker folds, poor overlap, etc., to ensure zero defects in factory products. The "cleverness" of this system lies in its adaptive learning ability. When changing the production version, the equipment can automatically identify the inspection standards of the new specification bags without manual re-adjustment, which does not affect the normal production rhythm at all. The 0.05% rejection rate is far beyond the limit of manual inspection, making product quality stable at a new level.

Real benefits: money is saved and efficiency is improved

The practice of a cement valve bag enterprise in Anhui is the most convincing: after the introduction of the collection system, the number of workers on a single production line was reduced from 5 to 2, saving more than 200,000 yuan in labor costs each year; the reduction in material waste has reduced the cost of raw materials by 15%, and the scrap rate has dropped from 1% to below 0.1%, and the overall benefits have been significantly improved.

These achievements are derived from the four core advantages of the system:

Cost reduction: a single production line reduces 1-2 bag picking workers, and with the technology of single-side lamination and reduced overlap width, the annual cost savings can reach hundreds of thousands;

Efficiency improvement: a stable speed of 120-130 bags/minute, 7×24 hours of continuous operation, so that the production capacity can be easily increased by 30%;

Quality preservation: a scrap rate of less than 0.1% helps the company establish a "high quality" reputation in the fierce competition;

Intelligence: the one-key number change function realizes fast specification switching, and the electric control system with free upgrades within 3 years makes the equipment never outdated.

From detection to management: data-driven production upgrade

The value of Gachn AI visual inspection system is not limited to eliminating waste. The system automatically records all defect data, generates defect classification and proportion reports, and provides enterprises with clear quality improvement directions. For example, when the proportion of "bottom sticker offset" defects increases, managers can quickly trace back to the parameter deviation of the heat sealing process, realizing the transformation from "passive quality inspection" to "active optimization".

This digital management capability allows enterprise decision makers to gain insight into production bottlenecks through data and gradually build a "zero defect" production system. As a customer in Fujian reported: "After installing the system, we can clearly explain the distribution of defect types in each shift for the first time, and process improvement has a clear goal."

Choose Gachn AI visual inspection system , choose peace of mind: not only equipment, but also a long-term partner

Gachn provides customers with full life cycle protection: 1-3 days of fast installation cycle does not delay production, on-site training ensures that workers can quickly get started, and the free upgrade of the electronic control system within three years keeps the technology up to date. At present, this set of equipment has been adapted to all imported and domestic plastic woven valve bag bag making machine models, and is running stably on the production lines of customers in Anhui, Jiangxi, Fujian, Guangxi and other places. When AI visual inspection becomes the industry standard, choosing Gachn group means choosing lower costs, higher efficiency and more stable quality. In the wave of intelligent transformation of the plastic woven valve bag industry, early layout can seize the market opportunity early - after all, in the competition where quality and cost determine the outcome, the difference of 0.05% missed inspection rate may be the life and death line between enterprises.