The working principle of the screen printing machine ① The working cycle program of the flat screen flat screen printing machine takes the flat screen platform type monochrome semi-automatic hand screen printing machine as an example. One of its working cycles is: feeding parts → positioning → printing → Lower the squeegee, raise the ink return plate → Squeegee stroke → Raise the squeegee → Lower the ink return plate → Lift the plate → Return ink stroke → Release positioning → Receiving.

In the continuous cycle action, as long as the function can be realized, the time occupied by each action should be as short as possible to shorten the period of each work cycle and improve the work efficiency.

③ Embossing line. During the printing stroke, the squeegee squeezes the ink and the screen printing plate, so that the screen printing plate and the substrate form a contact line, which is called a nip line. This line is at the edge of the squeegee, and countless embossed lines form the printing surface. Achieving an ideal nip line is difficult because the printing stroke is a dynamic process.

③The working principle of screen printing machine. Taking the commonly used hand-shaped screen printing machine as an example, the working principle of the screen printing machine can be described as follows: the power is transmitted through the transmission mechanism, and the squeegee squeezes the ink and the screen printing plate during the movement, so that the screen printing The printing plate and the substrate form an embossing line. Since the screen has tensions N1 and N2, a force F2 is generated on the squeegee. Under the action of the squeezing force F1 of the squeegee, through the mesh, the printing is missed from the moving embossing line to the substrate.

During the printing process, the screen printing plate and the squeegee move relative to each other, and the extrusion force F1 and the rebound force F2 also move synchronously. Dirty blots. That is, the screen is constantly deformed and rebounded during the printing stroke.

The squeegee is separated from the substrate together with the screen printing plate after the one-way printing is completed, and at the same time, the ink is returned to the back, that is, a printing cycle is completed. The distance between the top of the substrate and the reverse side of the screen printing plate after returning to ink is called the same plate distance or screen distance, which should generally be 2 to 5 mm. In manual printing, the operator's technique and proficiency directly affect the formation of the embossing line. In practice, screen printing workers have accumulated a lot of valuable experience, which can be summarized into six points, that is, to ensure the linearity, uniformity, isometric, pressure equalization, centering and verticality in the movement of the squeegee. That is to say, the squeegee should move in a straight line during printing, and it should not be shaken left and right; it should not be slow forward and fast, fast forward and then slow or suddenly slow and fast; the inclination angle to the ink plate should remain unchanged, and special attention should be paid to overcoming the inclination angle. A common problem that gradually increases; the printing pressure should be kept uniform; the distance between the squeegee and the inner side of the screen frame should be equal; the ink plate and the frame should be kept perpendicular

How Do Low-Temperature Air-Cooled Chillers Achieve Effective Heat Recovery

In modern industrial and building applications, the energy consumption of low-temperature air-cooled chillers is a growing concern. Recovering waste heat from these systems can significantly improve overall energy efficiency while reducing operational costs and environmental impact. So, how exactly does heat recovery work in these systems?

1. Using High-Efficiency Heat Exchangers

A key method for heat recovery is integrating high-efficiency heat exchangers into the chiller system.When the air-cooled chiller releases waste heat, this thermal energy is transferred to a secondary medium—such as water or air—inside the heat exchanger. The recovered heat can then be reused for:

• Preheating fresh air

• Supplying domestic hot water

• Industrial process heating

By using counter-flow heat exchange, hot and cold fluids make full thermal contact, maximizing heat transfer efficiency. Compact and efficient plate heat exchangers are particularly suitable for air-cooled chiller heat recovery due to their high thermal conductivity and small footprint.

2. Integrating Heat Pump Technology

Another effective approach is integrating heat pump technology into the system.Even though low-temperature air-cooled chillers operate at lower temperatures, their exhaust air or cooling loop still contains recoverable heat energy.

A heat pump can:

• Absorb low-grade heat from the chiller's exhaust

• Compress and elevate the temperature

• Deliver the upgraded heat to other applications

Using VRF (Variable Refrigerant Flow) heat pump systems allows flexible heat recovery according to real-time demand and adapts efficiently to varying operating conditions of the chiller.

3. Optimizing the Control System

A smart and precise control system is essential for effective heat recovery.The control system continuously monitors parameters such as:

• Temperature

• Pressure

• Flow rate

Based on real-time data, it adjusts the heat recovery equipment to ensure optimal performance.

When multiple heat-use terminals exist, the system must also intelligently distribute heat to meet different demands without wasting energy.

Conclusion

Through the combined use of high-efficiency heat exchangers, integrated heat pump technology, and intelligent control strategies, low-temperature air-cooled chillers can achieve substantial heat recovery. This not only enhances system energy efficiency but also contributes to greener and more economical operation.

Air Cooled Chiller vs Water Cooled Chiller The Ultimate Comparison

Air Cooled Chiller vs Water Cooled Chiller The Ultimate Comparison

When you ask which is better, an air cooled chiller or a water-cooled chiller, the real answer depends on your unique situation. You might focus on efficiency, cost, installation, maintenance, or even where you plan to use the chiller. Water-cooled chillers still hold the largest global market share, thanks to their high efficiency and popularity in large-scale industries. However, air cooled chiller technology has made huge leaps, especially with OUMAL’s advanced models that deliver reliable cooling, low maintenance, and a compact footprint. If you want a clear comparison, you’re in the right place.

Key Takeaways

-

Air-cooled chillers are ideal for areas with limited water supply. They are easy to install and maintain, making them a practical choice for many industries.

-

Water-cooled chillers offer high efficiency and are best for large-scale operations. They require a steady water supply and more complex installation.

-

Consider your cooling capacity needs. Air-cooled chillers work well for smaller applications, while water-cooled chillers excel in larger facilities.

-

Evaluate your location and environmental factors. Air-cooled chillers are better for remote areas, while water-cooled chillers suit urban settings with ample water.

-

Plan for long-term costs. Water-cooled chillers may have higher upfront costs but can save money on energy and maintenance over time.

What Is an Air Cooled Chiller?

If you want a cooling solution that’s simple, reliable, and efficient, you should look at an air-cooled chiller. This type of chiller uses air to remove heat from your process or equipment. You don’t need a big water supply or a cooling tower. That makes air-cooled chillers a great choice for many industries, especially where water is scarce or noise is a concern.

Let’s take OUMAL’s Air Cooled Screw Chillers as an example. These chillers use advanced screw compressors and smart controls to deliver precise temperature management. You get a compact design that fits into tight spaces and works well in places where you can’t install large water systems. OUMAL’s models also offer customization, so you can match your chiller to your exact needs.

How Air Cooled Chillers Work

You might wonder how an air-cooled chiller actually works. Here’s a quick breakdown. The chiller pulls heat from your process water in a closed loop. The chilled water moves through your equipment, picks up heat, and returns to the chiller. Inside the evaporator, the refrigerant absorbs this heat and turns into vapor. The compressor then squeezes this vapor into a high-pressure gas. Next, the gas flows to the condenser, where fans blow air over coils to cool it down. The refrigerant turns back into a liquid, drops in pressure and temperature, and starts the cycle again. This process keeps your system cool and running smoothly.

Key Features

Air-cooled chillers stand out because of their smart design and reliable parts. Here’s a quick look at the main components:

|

Component |

Function |

|---|---|

|

Compressor |

Pressurizes the refrigerant vapor, increasing its energy level for heat release in the condenser. |

|

Condenser |

Rejects heat absorbed by the refrigerant and transfers it to the surrounding air. |

|

Expansion Valve |

Regulates refrigerant flow and reduces pressure before entering the evaporator. |

|

Evaporator |

Absorbs heat from the chilled water, causing the refrigerant to evaporate into a gas. |

|

Fans |

Facilitate heat dissipation by forcing ambient air over the condenser coils. |

You’ll find that air-cooled chillers are easy to install and maintain. They don’t need extra water infrastructure, which saves you time and money. OUMAL’s air cooled chiller models also use durable materials, so you get long-lasting performance even in tough environments.

Common Applications

Air-cooled chillers work in many different industries. Here are some common uses:

|

Industry |

Application Description |

|---|---|

|

Commercial Buildings |

Used to maintain comfort levels by regulating indoor temperatures in office buildings. |

|

Data Centers |

Essential for cooling servers to prevent overheating and ensure optimal operating conditions. |

|

Manufacturing Facilities |

Provides temperature control in processes like chemical processing and plastic manufacturing. |

|

Food and Beverage Industry |

Ensures product integrity and safety through necessary cooling in storage and processing. |

You can see air-cooled chillers in action at poultry farms, data centers, and food processing plants. If you need a flexible, efficient, and reliable cooling solution, an air cooled chiller could be the perfect fit.

What Is a Water-Cooled Chiller?

You might wonder what makes a water-cooled chiller different from other cooling systems. A water-cooled chiller uses water to remove heat from your process or equipment. You will see these chillers in places where you need powerful cooling and have access to a steady water supply.

How Water-Cooled Chillers Work

A water-cooled chiller works by circulating water through a condenser. The process starts when the chiller absorbs heat from your system. The refrigerant picks up this heat and moves it to the condenser. Water flows through the condenser and carries the heat away. The cooled refrigerant then cycles back to absorb more heat. You need a cooling tower or another heat rejection device to release the heat from the water. This setup lets water-cooled chillers handle large cooling loads with high efficiency.

Key Features

Water-cooled chillers stand out for their strong performance and flexibility. Here are some features you will find:

-

High cooling capacity for demanding environments

-

Stable operation with precise temperature control

-

Quiet performance, making them suitable for noise-sensitive areas

-

Long lifespan with proper maintenance

-

Ability to operate in a wide range of climates

|

Feature |

Benefit |

|---|---|

|

Large cooling capacity |

Supports heavy-duty industrial processes |

|

Quiet operation |

Reduces noise in sensitive locations |

|

Efficient heat removal |

Maintains consistent cooling |

Common Applications

You will find water-cooled chillers in many industries. These chillers work well in places where you need reliable and powerful cooling. Here are some common uses:

Tip: Choose a water-cooled chiller if you have access to plenty of water and need high efficiency for large-scale operations.

-

Chemical processing plants

-

Pharmaceutical manufacturing

-

Data centers

-

Food and beverage production

-

Industrial facilities with continuous cooling needs

Water-cooled chillers help you keep your processes running smoothly. You get stable temperatures and efficient cooling, which is vital for sensitive equipment and products.

Air Cooled Chiller vs Water-Cooled Chiller Comparison

Pros and Cons of Air Cooled Chillers

When you look at air cooled chiller options, you’ll notice they offer a lot of practical benefits. You don’t need a constant water supply, so you can use them in places where water is scarce or expensive. The installation process is simple, and you can fit these chillers into smaller spaces. Maintenance is straightforward, and you won’t spend much time or money keeping them running.

Here’s a quick rundown of what you get with this chiller type:

-

Lower initial cost compared to water-cooled chillers.

-

Water-saving solution, perfect for regions where water conservation matters.

-

Small installation area required, so you can use them in tight spaces.

-

Easy and inexpensive maintenance, which saves you hassle.

-

Reliable performance in environments with limited water supply or noise restrictions.

But you should also know about the limitations. Air-cooled chillers usually have lower efficiency than water-cooled chillers, especially when you need to cool large spaces or run the system nonstop. The cooling capacity per unit is limited, so you might need multiple units for bigger jobs.

Note: The condensing temperature in air-cooled chillers depends on the ambient dry-bulb temperature. When it’s hot outside, the chiller works harder and uses more energy.

Here’s a table that sums up the main advantages and disadvantages:

|

Chiller Type |

Advantages |

Disadvantages |

|---|---|---|

|

Air Cooled Chiller |

Lower initial cost, water-saving, small footprint, easy maintenance |

Lower efficiency, limited capacity |

Pros and Cons of Water-Cooled Chillers

If you need high efficiency and powerful cooling, water-cooled chillers might be the best choice. You’ll find these chillers in large industrial plants and places where cooling demands are high. They handle big jobs with ease and keep energy costs down over time.

Here’s what you get with this chiller type:

-

High energy efficiency, especially in large-scale environments or continuous use.

-

Availability of large-capacity units for demanding applications.

-

Stable operation with precise temperature control.

-

Quiet performance, which is great for noise-sensitive areas.

However, water-cooled chillers come with higher initial costs and more complex installation. You need a steady water supply and extra infrastructure, like cooling towers. Maintenance can be more involved, and water consumption is high. There’s also a risk of Legionella bacteria if you don’t maintain the system properly.

Tip: Water-cooled chillers operate at lower condensing temperatures, so the compressor does less work and uses less energy. This leads to lower operating costs over time.

Here’s a table to help you compare:

|

Chiller Type |

Advantages |

Disadvantages |

|---|---|---|

|

Water-Cooled Chiller |

High efficiency, large capacity, quiet operation |

High initial cost, high maintenance, large footprint, water consumption, Legionella risk |

When you choose between these two chiller types, think about your priorities. If you want a simple, water-saving solution with easy maintenance, air-cooled chillers are a solid pick. If you need maximum efficiency and cooling power for a big facility, water-cooled chillers might suit you better.

Chiller Efficiency and Performance

Cooling Capacity

When you look at chiller efficiency, cooling capacity stands out as a key factor. You want a chiller that can handle your process demands, even when the weather changes. Air-cooled chillers, like OUMAL’s advanced models, deliver reliable cooling and precise temperature control. These chillers work well in moderate climates and can support a wide range of industrial needs. Water-cooled chillers, on the other hand, shine in large facilities where you need powerful cooling all year.

Here’s a quick comparison of how each type performs in hot climates:

|

Chiller Type |

Efficiency in High Temperatures |

Performance in Hot Climates |

|---|---|---|

|

Air-Cooled Chiller |

Less efficient |

Struggles to maintain capacity |

|

Water-Cooled Chiller |

More efficient |

Maintains better performance |

If you operate in a hot region, water-cooled chillers help you keep your cooling capacity steady. Air-cooled chillers may lose some efficiency when temperatures rise, but they still offer solid performance in cooler seasons.

Energy Use in Different Conditions

You care about energy efficiency because it affects your costs and your plant energy efficiency. Air-cooled chillers use fans to reject heat, so their energy use goes up when the outside air gets hot. In cooler climates or at night, these chillers can run efficiently and save you water. Water-cooled chillers use cooling towers and evaporation, which helps them keep energy consumption low, even when it’s hot outside.

Chiller energy efficiency changes with the seasons. Air-cooled chillers work best when the air is cool, but their efficiency drops in extreme heat. Water-cooled chillers stay consistent, making them ideal for facilities with high cooling demands. If you want to maximize energy efficiency, consider your climate and how often you need cooling.

Tip: If water is scarce or you want to simplify your setup, air-cooled chillers offer substantial water savings and easy installation.

You can boost your plant energy efficiency by choosing the right chiller for your environment. Think about your cooling capacity needs, local climate, and long-term energy use before you decide.

Installation and Space Needs

Footprint and Flexibility

When you plan your cooling system, space often becomes a big concern. Air-cooled chillers shine when you have limited room. You can place them outside your building, and they do not need extra equipment like cooling towers. This makes them a great fit for smaller or medium-sized spaces. If you work in a tight area or want to keep your indoor space free, air-cooled chillers give you more options.

Water-cooled chillers, on the other hand, need more space. You must set aside room for the chiller itself, plus extra space for cooling towers, pumps, and piping. These systems work best in larger facilities where you can dedicate a mechanical room or outdoor area for all the components.

Here’s a quick comparison:

|

Chiller Type |

Space Requirement |

|---|---|

|

Air-Cooled Chillers |

More suitable for limited space |

|

Water-Cooled Chillers |

Requires additional space for components |

You might find this helpful:

-

Air-cooled chillers work well for smaller to medium-sized applications.

-

Water-cooled chillers suit larger operations with higher cooling needs.

If you want to install your chiller outside, air-cooled systems are usually the top choice. Limited space? Benchtop air-cooled chillers can fit right in.

Infrastructure Requirements

You should also think about what each chiller needs to run smoothly. Air-cooled chillers keep things simple. You do not need a cooling tower or a complex water system. This means you can install them faster and with less hassle. Maintenance stays easy, too, since you do not have to worry about water treatment.

Water-cooled chillers require more planning. You need to install cooling towers, pumps, and extra piping. This setup takes more time and costs more upfront. You also have to maintain the water system, which adds to your workload.

Here’s a side-by-side look:

|

Feature |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Installation Complexity |

Simpler, no cooling towers needed |

More complex, needs towers and pumps |

|

Upfront Costs |

Lower, fewer components |

Higher, more infrastructure |

|

Maintenance Needs |

Easier, no water treatment |

More involved, water system upkeep |

|

Water Dependency |

Not dependent on water supply |

Needs a steady water supply |

If you want a system that is quick to set up and easy to maintain, air-cooled chillers make your life easier. For bigger projects where space and water are not issues, water-cooled chillers can deliver the power you need.

Cost Breakdown

Initial and Installation Costs

When you start planning for a new chiller, the first cost often becomes your biggest concern. You want to know how much you’ll spend upfront before you even think about running the system. Air-cooled chillers usually have a lower first cost compared to water-cooled chillers. You don’t need extra equipment like cooling towers or pumps, so installation stays simple and quick.

Take a look at this table to see how the first cost compares for a 200-ton chiller:

|

Chiller Type |

Cost (200-ton) |

|---|---|

|

Air-Cooled Chiller |

$250,000 |

|

Water-Cooled Chiller |

$340,000 |

If you break it down by ton, air-cooled chillers average about $150 per ton for equipment only, while water-cooled chillers come in closer to $200 per ton. You save on first cost with air-cooled models, especially if you need a system that’s easy to install and doesn’t require a lot of extra infrastructure.

Tip: Always consider the first cost, but remember that installation expenses can add up if your site needs extra piping or water treatment systems.

Operating and Maintenance Costs

Once your chiller is up and running, you’ll start thinking about operating costs. These costs include the energy needed to keep your system cool and the regular work required to keep everything in good shape. Over time, operating costs can make a big difference in your budget.

Air-cooled chillers often need more frequent attention. You’ll find yourself cleaning coils and checking fans throughout the cooling season. This regular upkeep means higher maintenance costs over the years. Water-cooled chillers, on the other hand, usually require less frequent maintenance. You might only need to clean condenser tubes once a year and handle some water treatment. This setup can lead to lower operating costs over a 10-year period.

If you want to keep your long-term expenses low, water-cooled chillers might offer better value despite their higher first cost. Air-cooled chillers give you a lower first cost, but you should plan for higher operating costs as time goes on.

Environmental and Location Factors

Water Availability

Water supply can make or break your chiller choice. If you live in a region with plenty of water, water-cooled chillers often work best. They deliver higher efficiency and use less energy. In places where water is scarce or expensive, air-cooled chillers step up. You avoid the hassle and cost of water use. For example, in the Middle East, air-cooled chillers help you sidestep water shortages and high bills.

Here’s a quick look at how geography affects your decision:

|

Region Type |

Preferred Chiller Type |

Reason for Preference |

|---|---|---|

|

Water-abundant |

Water-cooled chillers |

Higher efficiency and lower energy consumption |

|

Water-scarce |

Air-cooled chillers |

Avoids complications and costs associated with water use |

-

In areas with strict water conservation rules, air-cooled chillers are often the top pick.

-

Water-cooled chillers may not work well where water use faces heavy regulation.

Noise and Surroundings

Noise matters, especially if you work in a city or near homes. Air-cooled chillers tend to be louder. They can reach noise levels like a busy street or a vacuum cleaner. Water-cooled chillers run much quieter, more like background music or a friendly chat. If you want to keep the peace in your neighborhood, water-cooled chillers might suit you better.

|

Chiller Type |

Noise Level (dB) |

Description |

|---|---|---|

|

Air-Cooled Chillers |

70 to 80 |

Comparable to a vacuum cleaner or busy street |

|

Water-Cooled Chillers |

55 to 65 |

Similar to a conversation or background music |

-

Air-cooled chillers: 70–80 dB, can be disruptive in residential areas.

-

Water-cooled chillers: 55–65 dB, better for noise-sensitive locations.

Urban vs Remote Suitability

Your location shapes your chiller needs. In cities, space and noise often matter most. Water-cooled chillers fit well in large buildings with room for extra equipment. In remote areas, you might not have water or infrastructure. Air-cooled chillers shine here. They need less maintenance, work well in harsh weather, and don’t rely on water.

-

Air-cooled chillers suit remote sites with limited water and infrastructure.

-

Water-cooled chillers work best in urban settings with stable water supply and space for cooling towers.

Tip: If you run operations in a remote or water-limited area, air-cooled chillers offer a practical and reliable solution.

Longevity and Reliability

Expected Lifespan

When you invest in a chiller, you want it to last. Air-cooled chillers usually give you reliable service for about 15 to 20 years. Water-cooled chillers tend to last longer, often between 20 and 30 years. The difference comes from how each system handles heat and the environment around it. If you run your equipment in a clean, well-maintained space, you can help extend its life.

Here’s a quick look at the average lifespan for each type:

|

Chiller Type |

Average Lifespan (Years) |

|---|---|

|

Air-cooled Chiller |

15 to 20 |

|

Water-cooled Chiller |

20 to 30 |

You might choose an air-cooled chiller for its simple setup and easy access. If you want a system that can go the distance, water-cooled chillers often deliver more years of service.

Maintenance Considerations

Keeping your chiller running smoothly means regular attention. You need to focus on chiller maintenance to avoid unexpected breakdowns and keep your cooling system efficient. Air-cooled chillers require you to clean condenser coils, check for refrigerant leaks, and watch for compressor issues. Water-cooled chillers need extra steps, like water treatment and monitoring water flow.

Here are some common maintenance tasks you’ll face:

-

Cleaning coils and removing debris

-

Inspecting refrigerant levels and electrical connections

-

Treating water to prevent scale and corrosion

-

Lubricating moving parts

-

Testing performance and calibrating controls

-

Replacing filters

-

Detecting leaks

If you manage plant service and maintenance, you know that regular checks help prevent high energy use and costly repairs. Dirty coils, leaks, or poor water quality can lead to problems. Staying on top of these tasks keeps your chiller reliable and extends its lifespan.

Tip: Set up a maintenance schedule and stick to it. You’ll save money and avoid downtime.

Choosing the Right Chiller

Decision Checklist

You want to make sure you pick the best chiller for your needs. Here’s a simple checklist to help you decide:

-

Cooling capacity requirements: Water-cooled chillers handle larger loads more efficiently.

-

Space and installation needs: Air-cooled systems work well if you have limited space or need outdoor installation.

-

Environmental conditions: Air-cooled chillers perform better in cooler climates. Water-cooled chillers are more efficient in hot or humid areas.

-

Long-term costs: Water-cooled chillers may cost more upfront but can save you money on energy over time.

-

Maintenance and design: Air-cooled chillers offer lower maintenance costs and easier installation. They also work well in freezing temperatures.

-

Equipment life: Water-cooled chillers often last longer and support bigger operations.

-

Your long-term goals: Consider all these factors to make sure your choice matches your future plans.

Tip: Write down your priorities before you start shopping. This helps you stay focused and avoid surprises later.

Application Scenarios

Let’s look at some real-world situations where each chiller type shines:

-

Construction sites need air-cooled chillers to keep workers safe during hot months. Quick setup and easy relocation make them ideal.

-

Data centers use air-cooled chillers for scalable cooling during upgrades or unexpected spikes. You get reliable performance and less downtime.

-

Manufacturing plants rely on air-cooled chillers to keep processes stable during heat-generating operations. Consistent cooling means better product quality.

-

Large events and entertainment venues choose air-cooled chillers for temporary cooling. Attendees stay comfortable, and organizers avoid heat-related issues.

-

Emergency response teams deploy air-cooled chillers in disaster areas. Fast installation provides critical cooling for shelters and operations.

If you run a facility with high cooling demands and plenty of space, water-cooled chillers might be the better fit. They offer greater efficiency and longer service life for big projects.

You face a choice between air cooled chiller and water-cooled chillers based on your plant size, budget, climate, and long-term goals. Here’s a quick look:

|

Factor |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Capacity |

Smaller plants |

Larger plants |

|

Installation |

Simple, outdoor |

Complex, indoor |

|

Efficiency |

Varies by climate |

Consistent, high |

Think about your cooling needs, available space, and future plans. If you want smart technology and reliability, check out OUMAL’s air cooled chiller models. Take time to list your priorities before you decide.

FAQ

What’s the main difference between air cooled and water-cooled chillers?

You use air cooled chillers when you want to cool with air. Water-cooled chillers use water to remove heat. Air cooled chillers work well in places with limited water. Water-cooled chillers suit bigger jobs and steady water supply.

Can I install an air cooled chiller outside?

Yes, you can place air cooled chillers outdoors. Their design handles weather changes. You save indoor space and avoid extra equipment. Just make sure you have enough airflow around the unit.

How often should I maintain my chiller?

You should check your chiller every month. Clean coils, inspect fans, and look for leaks. Water-cooled chillers need water treatment and annual tube cleaning. Regular care keeps your system running smoothly.

Which chiller is quieter?

Water-cooled chillers usually run quieter than air cooled chillers. If you need low noise for your site, water-cooled models help you keep the peace. Air cooled chillers may sound louder because of their fans.

How Glycol Cooled Chillers Protect Equipment and Extend Lifespan

A glycol cooled chiller protects your equipment by maintaining precise temperatures and preventing overheating. You benefit from reduced emergency repair costs and longer equipment lifespan. For example:

-

A Hull chemical plant lowered annual repair costs from £7,400 to £1,870 after improving their cooling system.

-

A Leeds printing firm extended the lifespan of press controllers by 2.3 years, saving on frequent replacements.

Choosing the right cooling solution ensures reliable operations and significant cost savings.

Key Takeaways

-

Glycol cooled chillers maintain stable temperatures, preventing overheating and protecting sensitive equipment.

-

Using glycol chillers can significantly reduce repair costs, as seen in a Hull chemical plant that cut costs from £7,400 to £1,870.

-

These chillers extend equipment lifespan by preventing thermal shock and mechanical stress, leading to fewer breakdowns.

-

Glycol solutions contain corrosion inhibitors that protect metal parts, reducing leaks and maintenance needs.

-

Regular maintenance and proper glycol concentration are essential for optimal performance and freeze protection.

-

Glycol chillers improve energy efficiency, helping facilities save on utility bills while maintaining reliable cooling.

-

Industries like food and beverage, data centers, and medical facilities benefit from precise temperature control provided by glycol chillers.

-

Investing in glycol cooled chillers ensures long-term operational efficiency and reliability for your equipment.

Glycol Cooled Chiller Protection

Glycol cooled chillers deliver both immediate and long-term protection for your equipment. You can rely on these chiller systems to keep your operations running smoothly, whether you manage industrial water chillers or commercial water coolers. Let’s explore how these systems safeguard your assets from day one and continue to provide value over many years.

Immediate Safeguards

You need consistent cooling to prevent sudden temperature spikes that can damage sensitive machinery. Glycol chillers maintain a stable temperature range, which is essential for equipment that operates continuously. When you use a glycol cooled chiller, you ensure that your chiller systems deliver reliable performance, even during peak loads. This stability reduces the risk of thermal shock, which can cause cracks or warping in metal components.

Overheating remains one of the most common causes of equipment failure in industrial and commercial settings. Glycol chillers address this risk by circulating a glycol-water mixture that absorbs and removes excess heat efficiently. You protect your machinery from overheating, which can lead to sudden breakdowns or permanent damage. By integrating glycol cooled chiller systems into your cooling systems, you create a buffer against unexpected temperature surges.

Long-Term Equipment Benefits

When you invest in glycol chillers, you gain more than just immediate protection. These chiller systems offer significant long-term benefits that extend the lifespan of your equipment and reduce the frequency of repairs.

|

Benefit |

Description |

|---|---|

|

Control of Heating and Cooling |

Propylene glycol helps maintain a constant cooling output, preventing overload and freezing conditions. |

|

Protection Against Frost |

Lowers the freezing temperature when mixed with water, preventing freezing in pipes and coils. |

|

Prevention Of Oxidation |

Contains corrosion inhibitors to protect metal components from rust and scale accumulation. |

You will notice that glycol chillers not only control heating and cooling but also protect against frost and oxidation. These features are especially important for industrial water chillers and commercial water coolers that operate in challenging environments. By preventing freezing and corrosion, you reduce the risk of leaks, blockages, and mechanical wear.

-

The average lifespan of a glycol cooled chiller reaches about 15-20 years, depending on how well you maintain and operate the system.

-

With regular maintenance and timely repairs, your chiller systems can last between 15 to 25 years, providing reliable service and minimizing equipment degradation.

You benefit from fewer breakdowns and lower maintenance costs over time. Glycol chillers help you avoid the frequent replacement of expensive components, which translates to substantial savings. When you choose glycol cooled chiller systems for your facility, you make a smart investment in the durability and efficiency of your equipment.

What Are Glycol Chillers?

Glycol chillers play a vital role in industrial and commercial cooling. You rely on these systems to maintain precise temperatures and protect your equipment from harsh conditions. Understanding how glycol chillers work helps you make informed decisions about your facility’s cooling needs.

A glycol chiller system uses several key components to deliver reliable performance and equipment protection. Each part serves a specific function to ensure smooth operation and long-term durability.

|

Component |

Description |

|---|---|

|

Glycol |

Acts as a heat transfer medium with antifreeze properties, essential for maintaining optimal temperatures. |

|

Refrigerant |

Transfers heat by changing states from liquid to gas and back, crucial for the cooling cycle. |

|

Corrosion Inhibitor |

Forms a protective film to prevent corrosion, essential for the longevity of the chiller system. |

|

Scale Inhibitor |

Prevents scale deposits on metal surfaces, which can cause inefficiency and damage. |

|

Biocide |

Kills bacteria and prevents biofilm, protecting the system from organic growth that can lead to fouling. |

You benefit from this combination of components because they work together to provide freeze protection, prevent corrosion, and reduce the risk of scale buildup. This design keeps your equipment running efficiently and extends its lifespan.

Why Use Glycol?

You might wonder why glycol is preferred over water in many chiller systems. Glycol offers several advantages that make it the best choice for demanding environments.

Freeze protection stands as the most important reason to use glycol chillers. Glycol lowers the freezing point of the cooling fluid, which keeps your system safe during cold weather or low-temperature operations. When you use glycol, you avoid frozen pipes and blocked lines that can cause costly damage.

-

Glycol’s antifreeze properties prevent internal piping from freezing, even when temperatures drop well below freezing.

-

Higher glycol concentrations lower the freezing point further, giving you greater freeze protection.

-

For example, a 60% ethylene glycol solution can lower the freezing point to -60°F, making it ideal for extreme conditions.

-

You must balance the concentration, though. Too much glycol increases viscosity and reduces heat transfer efficiency, which can affect system performance.

|

Glycol Type |

Volume % |

Freezing Point °F |

|---|---|---|

|

Propylene Glycol |

20.4 |

18.3 |

|

Propylene Glycol |

30.4 |

7.9 |

|

Ethylene Glycol |

22.0 |

14.0 |

|

Ethylene Glycol |

37.5 |

-11.2 |

|

Ethylene Glycol |

45.5 |

-27.4 |

|

Ethylene Glycol |

57.8 |

-59.8 |

Note: Always check local regulations for glycol disposal and handling. Proper management protects the environment and keeps your facility compliant.

Glycol chillers also help you maintain efficient heat exchange. Glycol supports stable operation under low temperatures, which improves temperature stability. You get reliable cooling and heating performance, even in challenging environments. Glycol’s properties allow your system to deliver consistent results, reducing the risk of thermal stress and equipment failure.

-

Glycol maintains efficient heat transfer, making it ideal for both cooling and heating applications.

-

You benefit from smooth operation and fewer interruptions, which supports long-term equipment health.

By choosing glycol chillers, you ensure your facility receives the best freeze protection and heat transfer efficiency available.

Benefits of Glycol Chillers

When you choose glycol chillers, you unlock a range of benefits that protect your equipment and improve your facility’s performance. These systems deliver more than just cooling—they provide corrosion protection, temperature stability, and energy efficiency. Understanding these advantages helps you maximize cost efficiency and extend the lifespan of your assets.

Corrosion Protection

Corrosion poses a major threat to industrial and commercial equipment. Metal components exposed to water and oxygen can rust, weaken, or develop leaks. Glycol chillers address this challenge by using specially formulated fluids that include corrosion inhibitors. These additives form a protective barrier on metal surfaces, reducing the risk of rust and scale buildup.

You benefit from fewer leaks and less downtime. Corrosion can cause blockages in pipes and coils, leading to expensive repairs or replacements. By preventing corrosion, glycol chillers help you maintain smooth operation and avoid unexpected failures. Propylene glycol benefits include enhanced protection for copper, steel, and aluminum parts. This protection is especially important in environments where water quality varies or where equipment runs continuously.

A well-maintained glycol chiller system reduces the frequency of maintenance tasks related to corrosion. You spend less time and money on cleaning, flushing, and replacing corroded parts. Over time, this translates to significant cost efficiency and improved reliability for your entire operation.

Temperature Stability

Maintaining stable temperatures is critical for many industrial processes. Glycol chillers excel in delivering precise thermal control, which ensures consistent product quality and equipment performance. You avoid temperature swings that can damage sensitive machinery or compromise production outcomes.

-

Fermentation Control: Glycol chillers allow precise temperature settings for fermentation, crucial for yeast activity and flavor production.

-

Batch Consistency: They eliminate temperature fluctuations, ensuring each batch of beer maintains the intended quality and flavor.

-

Preservation of Freshness & Flavor: By maintaining optimal temperatures, glycol chillers prevent oxidation and spoilage, extending shelf life and preserving taste.

-

Freezing Prevention: Glycol's antifreeze properties ensure reliable operation in cold environments, preventing damage to brewing equipment.

You see the benefits of temperature stability in industries like brewing, food processing, and pharmaceuticals. Propylene glycol benefits include the ability to fine-tune cooling for each stage of production. This level of control helps you deliver consistent results and meet strict quality standards.

Temperature stability also reduces the risk of thermal shock, which can crack or warp metal parts. By keeping your equipment within safe operating ranges, you extend its lifespan and reduce the likelihood of costly breakdowns.

Energy Efficiency

Energy efficiency remains a top priority for any facility manager. Glycol chillers offer several ways to optimize energy use, but you must understand their unique characteristics to achieve the best results.Glycol is more viscous than water, particularly at lower temperatures. As a result, more energy is required to circulate glycol solutions through the loop. This increased energy consumption can affect system economics over time, especially in large or high-demand applications. Additionally, glycol has a lower specific heat capacity than water, meaning it absorbs and transfers less heat per unit of fluid. This reduces the system’s cooling capacity and may require larger heat exchangers or longer run times to handle the same heat load.

Despite these considerations, you can still achieve cost efficiency by selecting the right glycol concentration and maintaining your system properly. Modern glycol chillers use advanced controls and variable-speed pumps to minimize energy waste. You benefit from lower utility bills and reduced environmental impact when you optimize your system for energy efficiency.

Regular maintenance, such as checking fluid levels and cleaning heat exchangers, further improves energy efficiency. You keep your equipment running at peak performance, which supports long-term savings and reliable operation.

Freeze Prevention & Temperature Control

Below-Freezing Operation

You face unique challenges when your facility operates in environments where temperatures regularly fall below freezing. Glycol cooled chillers provide a robust solution for freeze prevention, ensuring your equipment runs smoothly even in harsh conditions. Glycol lowers the freezing point of fluids, which keeps your pipes and coils free from ice buildup. This feature protects your system from costly damage and unexpected shutdowns.

You also benefit from corrosion resistance. Glycol solutions contain inhibitors that shield metal surfaces from rust and scale. This protection maintains the integrity of your cooling system, reducing the risk of leaks and blockages. Efficient heat transfer is another advantage. Glycol enables reliable operation by moving heat away from sensitive components, which is essential for both cooling and heating applications.

-

Glycol lowers the freezing point of fluids, preventing ice formation in cold environments.

-

Corrosion inhibitors in glycol solutions protect metal surfaces and extend equipment lifespan.

-

Efficient heat transfer supports reliable operation in demanding conditions.

Tip: Regularly monitor your glycol concentration to maintain optimal freeze protection and temperature control. This practice helps you avoid performance issues and costly repairs.

Precise Thermal Management

Precise thermal management plays a critical role in laboratory and manufacturing settings. You need consistent temperature control to maintain product quality and process efficiency. Glycol cooled chillers deliver stable temperatures, which supports high first-pass yield rates and reduces defects. You see measurable improvements in your operations when you invest in advanced cooling solutions.

|

Benefit Type |

Description |

|---|---|

|

Process Efficiency |

Cycle times in manufacturing drop by 8-15%, leading to higher production capability without extra costs. |

|

Quality Metrics |

First-pass yield rates increase by 5-10%, reducing defects and raw material consumption. |

|

Energy Efficiency |

15-20% decrease in cooling-related energy use due to stable temperature operation. |

You gain higher production capability and lower energy costs. Stable temperature control reduces the risk of thermal shock, which can damage sensitive equipment. You also minimize raw material waste and improve overall product quality. Glycol cooled chillers help you maintain precise conditions, which is vital for research, testing, and production environments.

Maintaining precise temperature control with glycol chillers supports consistent results and long-term reliability. You protect your investment and ensure your facility meets industry standards.

Reducing Wear and Maintenance

You want your equipment to last as long as possible. Glycol cooled chillers help you achieve this by reducing mechanical stress on your machinery. When you use a glycol solution, your cooling system operates at lower pressures and more stable temperatures. This stability means your pumps, compressors, and pipes do not experience sudden changes that can cause fatigue or failure.

Glycol acts as a buffer, absorbing temperature swings and preventing rapid expansion or contraction of metal parts. This process keeps your system running smoothly, even during demanding cycles. You avoid the harsh start-stop cycles that often lead to cracks, leaks, or worn seals. As a result, your equipment faces less strain each day.

You also benefit from improved energy efficiency. Lower operating pressures and temperatures mean your system does not have to work as hard. This efficiency reduces wear on moving parts and extends the life of your components. Over time, you see fewer emergency repairs and less downtime.

Here is how reduced mechanical stress translates into lower maintenance requirements:

|

Benefit |

Explanation |

|---|---|

|

Longevity |

Durable components lead to a longer lifespan, reducing the frequency of maintenance and replacements. |

|

Energy Efficiency |

Lower operating pressures and temperatures enhance efficiency, which can minimize wear and tear.

|

Regular monitoring of your glycol levels ensures your system continues to operate under optimal conditions, further reducing mechanical stress.

Fewer Breakdowns

You know that frequent breakdowns disrupt your workflow and increase costs. Glycol cooled chillers help you avoid these issues by providing consistent protection against the main causes of equipment failure. Stable temperatures and corrosion inhibitors work together to keep your system in top shape.

When your equipment runs at a steady temperature, you prevent thermal shock. This protection stops metal parts from warping or cracking. Corrosion inhibitors in glycol solutions also shield your pipes and coils from rust and scale. You avoid blockages that can lead to sudden shutdowns.

You spend less time on emergency repairs and more time on productive work. Maintenance teams can focus on routine checks instead of urgent fixes. This shift leads to a safer and more predictable work environment.

-

You reduce the risk of leaks and mechanical failures.

-

You extend the service intervals for pumps, valves, and compressors.

-

You lower your total cost of ownership by minimizing unplanned downtime.

You need to follow best practices for maintaining glycol to maximize the lifespan and reliability of your chiller systems. Proper glycol concentration and routine maintenance play a critical role in protecting your equipment and ensuring efficient operation.

Maintaining the correct glycol concentration is essential for freeze protection and optimal heat transfer. You should always check the glycol levels to avoid problems such as freezing, corrosion, or reduced cooling performance.

|

Glycol Concentration |

Purpose |

|---|---|

|

25% |

Minimum level for biostatic properties |

|

25% to 50% |

Optimal for freeze protection and heat transfer capabilities |

You must test glycol concentration regularly to keep your system running smoothly. Routine testing helps you detect issues before they affect performance or safety.

|

Test Type |

Interval |

|---|---|

|

Coolant Test |

6 months (Standard) |

|

|

12 months (Extended Life) |

Schedule coolant tests every six months for standard systems. For extended life systems, you can test every twelve months. Use a refractometer or test strips to measure glycol levels accurately. Adjust the concentration as needed to stay within the recommended range. Regular testing ensures your system remains protected against freezing and corrosion.

Tip: Always record your test results and adjustments. Keeping a log helps you track trends and spot potential problems early.

Risks of Incorrect Levels

Incorrect glycol concentration can disrupt your chiller’s efficiency and safety. Too little glycol increases the risk of freezing and corrosion. Too much glycol reduces heat transfer and raises energy costs. Contaminated glycol can introduce toxic substances, leading to health hazards and environmental risks. In regulated industries, even minor contamination may result in costly shutdowns or compliance violations. Mechanical degradation and increased maintenance needs often follow improper concentration.

Routine maintenance keeps your glycol cooled chiller operating at peak performance. You should inspect all system components, monitor water quality, and assess compressor health. Address potential issues proactively to maximize efficiency and durability.

|

Maintenance Practice |

Description |

|---|---|

|

Regular Inspections |

Routine checks of all components to identify leaks and ensure proper refrigerant levels. |

|

Water Quality Management |

Monitoring and treatment of condenser water to prevent scaling, corrosion, and biological growth. |

|

Compressor Health Assessments |

Regular vibration analysis and electrical checks to ensure compressor and motor functionality. |

|

Glycol Management |

Proper management of glycol mixtures, including regular monitoring and maintenance. |

|

Preventative Maintenance |

Adhering to manufacturer-recommended service schedules and utilizing qualified technicians. |

-

Clean heat exchangers and evaporators.

-

Check for leaks in glycol lines.

-

Replace worn-out components such as pumps, valves, and sensors.

-

Flush and replace glycol mixtures if needed.

-

Follow recommended shutdown procedures to prevent refrigerant migration.

Proactive maintenance during downtime prevents unexpected failures during peak production periods. Extended shutdowns can cause refrigerant migration, leading to hard starts and damage. You should always follow proper shutdown procedures to avoid these risks.Regular monitoring and maintenance help you avoid costly repairs and extend the lifespan of your equipment.

Industry Applications

Glycol cooled chillers serve a wide range of applications across industries that demand reliable temperature control and equipment protection. You can see their impact in food and beverage production, data centers, and medical facilities. Each sector faces unique challenges, and glycol chillers address these needs with tailored solutions.

You rely on glycol cooled chillers to maintain product quality and safeguard equipment in food and beverage processing. These chillers provide reliable solutions for manufacturing environments, ensuring consistent performance and safety. You benefit from rapid cooling after processes like pasteurization, which preserves flavor and texture. Glycol chillers help you control microbial growth, a critical factor for food safety. You maintain HACCP compliance by keeping products in safe temperature zones during production, storage, and packaging.

-

Control microbial growth for food safety.

-

Preserve flavor and texture of products.

-

Enable rapid cooling after thermal processes.

-

Maintain compliance with safety standards.

-

Prevent spoilage and ensure batch consistency.

-

Enhance operational efficiency with precise thermal management.

You see these advantages in breweries, dairies, and food processing plants. Glycol cooled chillers rapidly lower the temperature of liquids, which is crucial for maintaining product integrity. You protect your equipment from insulation degradation and heat gain, even in cluttered layouts.

|

Industry |

Unique Protection Requirements |

|---|---|

|

Breweries |

Insulation degradation, heat gain, cluttered layouts |

|

Dairies |

Insulation degradation, heat gain, cluttered layouts |

You depend on glycol cooled chillers to keep data centers and IT environments running smoothly. These chillers provide efficient cooling solutions that support continuous operation. You achieve precise temperature control, which is vital for uptime and reliability. Advanced cooling systems integrate redundancy features, helping you prevent downtime and maintain business continuity.

-

Provide efficient cooling for IT equipment.

-

Ensure precise temperature control for continuous operation.

-

Integrate redundancy to enhance reliability.

-

Prevent costly downtime and equipment failures.

You face challenges such as insulation degradation and heat gain in data centers. Glycol cooled chillers address these issues, allowing you to maintain optimal conditions in complex and cluttered environments.

|

Industry |

Unique Protection Requirements |

|---|---|

|

Data Centers |

Insulation degradation, heat gain, cluttered layouts |

Medical & Laboratory

You trust glycol cooled chillers to deliver precise temperature control in medical facilities and laboratory settings. These chillers support temperature-sensitive processes, which are essential for patient outcomes and research accuracy. You rely on consistent performance to prevent unexpected shutdowns and costly repairs. Glycol chillers offer versatility and adaptability, making them suitable for imaging equipment, pharmaceutical storage, and other critical applications in medical facilities.

|

Benefit |

Description |

|---|---|

|

Enhanced Temperature Control |

Glycol chillers provide precise temperature control, crucial for medical devices and patient outcomes. |

|

Consistent Performance |

They ensure reliable cooling, preventing unexpected shutdowns and costly repairs. |

|

Versatility and Adaptability |

Suitable for various applications, from imaging equipment to pharmaceutical storage. |

You see glycol cooled chillers used in medical facilities for everything from laboratory incubators to MRI machines. These chillers help you maintain strict temperature requirements, which protect sensitive equipment and ensure accurate results. You benefit from reliable cooling that supports a safe and efficient environment in medical facilities.

Tip: Glycol cooled chillers offer proven solutions for medical facilities, supporting a wide range of applications and ensuring long-term reliability.

You protect your equipment and extend its lifespan by choosing a glycol cooled chiller. Regular inspections, glycol quality testing, and monitoring system pressure help you prevent leaks and corrosion. Effective water treatment and flushing routines enhance reliability and reduce wear.

Applying best practices for glycol cooled chiller maintenance leads to fewer breakdowns, lower operating costs, and long-term operational efficiency. Investing in these systems ensures safe, reliable performance for years.

Surprising Water Cooled Scroll Chiller Tips for Your Building

You should always begin with correct cooling load calculations when picking a water cooled scroll chiller. This step helps you avoid mistakes and makes sure your equipment fits your facility. See how the right size affects your operation:

|

Benefit |

Description |

|---|---|

|

Optimized System Performance |

Makes industrial cooling systems work their best and keeps process temperatures steady. |

|

Energy Savings |

Right-sized chillers use less energy and lower your factory's utility bills. |

|

Longer System Lifespan |

Efficient chillers do not work as hard, so they break less and need fewer repairs. |

|

Production Stability |

Better cooling performance and lower downtime make production lines more efficient. |

You will see that thinking about long-term savings, not just the first price, is smart. Get ready for helpful tips and industrial cooling advice that may surprise you.

Key Takeaways

-

First, make sure you know how much cooling your industrial process needs. This helps you pick the right water cooled scroll chiller. Plan regular maintenance so your chilling system works well. Pick a chiller that fits your plant’s cooling demand to stop energy waste and expensive fixes. Look at energy ratings like COP and IPLV. These ratings help you save money and help the environment. Talk to your chiller expert about future expansion to make sure your chiller can handle growth.

Know Your Cooling Needs

Process Load & Heat Analysis

You need to start with a clear understanding of your building’s cooling needs. This step helps you choose a water cooled scroll chiller that fits your space and keeps your process cooling system running smoothly. You should not guess your cooling load. Instead, use a block load and heat analysis to get accurate numbers.

Heat analysis checks how much heat your facility gains from machinery, materials, and the surrounding environment. These numbers help you pick the right chiller size.

Tip: If you oversize your chiller, you waste energy and money. If you undersize it, your equipment will not stay cool enough for production.

Industry standards guide you through this process. The table below shows some important standards you should know:

|

Standard |

Description |

|---|---|

|

AHRI 550/590 |

Gives a consistent way to calculate part-load performance. Focuses on full system analysis for best efficiency. |

|

IPLV |

Used to check single chiller performance. Not meant for figuring out total operating costs. |

|

Comprehensive Analysis |

Includes ambient data, process load, and extra energy use for a true picture of efficiency. |

You should always use accurate data and factory details in your calculations. This approach helps you avoid costly mistakes and keeps your chilling system efficient.

Planning for Growth

Your production line may change over time. You might add new machines, expand your plant, or change your cooling requirements. You need to plan for these changes when you choose your chiller.

Think about these steps:

-

Review your cooling needs at least twice a year during different production peaks.

-

Schedule professional maintenance once or twice a year for your industrial cooling system.

-

Ask your technical staff to check simple things, like water filters, every month.

Note: Regular reviews help you spot problems early and adjust your chiller system before small issues become big ones.

If you expect your business to grow, talk to your chiller manufacturer about future needs. You can choose a chiller with extra capacity or a modular design that is easy to upgrade.

Water Cooled Scroll Chiller Selection

Chiller Type Comparison

You have to pick between air-cooled and water cooled scroll chillers. Each one has specific benefits for industrial environments. Your choice changes how stable your process cooling is.

|

Feature |

Air-Cooled Chillers |

Water-Cooled Chillers |

|---|---|---|

|

Efficiency |

Affected by hot ambient air |

Works better, especially for heavy industrial use |

|

Installation |

Faster and easier setup |

Needs cooling tower and water pumps |

|

Maintenance |

Simpler with fewer components |

Needs water treatment and tower checks |

|

Cost |

Lower upfront cost |

Costs more at first, but saves energy later |

Water cooled scroll chillers are best for factories that need massive, consistent cooling. If you want the most efficient process cooling system, pick water cooled scroll chillers.

Tip: Water cooled scroll chillers work great for plastic injection, data centers, and chemical plants. They cool industrial spaces and keep energy use low.

Matching Capacity to Demand

You need to make sure your water cooled scroll chiller matches your industrial demand. This helps your chilling system work well and saves money.

Here is how you can get the right size:

-

Figure out the heat load from your production machinery and raw materials.

-

Check your local climate. Industrial plants in hotter regions need more robust condenser heat rejection.

-

Pick the precise coolant temperature required for your specific industrial application.

|

Factor |

Description |

|---|---|

|

Cooling Capacity |

The heat output of your production line decides the chiller size. |

|

Refrigerant Selection |

The refrigerant changes how well your industrial cooling system works and its eco-impact. |

Do not think that bigger is always better. If your scroll chiller is too big, it "short cycles," wasting energy and wearing out the compressor. Always use the right numbers before you pick an Oumal water cooled scroll chiller.

Chiller Efficiency & Performance

Key Ratings (COP, IPLV)

You need to look at two main ratings: COP and IPLV. COP shows how well your chiller turns electricity into process cooling. Higher COP means better efficiency for your chilling system and lower overhead costs.

|

Rated Cooling Capacity (KW) |

Minimum COP |

|---|---|

| Less than 528 | 3.8 |

| Greater than 1163 | 4.2 |

IPLV is vital for industrial applications where the heat load varies throughout the day. It shows how the chiller performs at part-load, which is where it spends most of its time.

Installation & Space Factors

Maintenance Access

You must leave enough space around your industrial water chiller for regular maintenance tips. Experts say you need at least 2 to 3 feet in front of the unit. This space lets technicians clean condensers and check compressors safely. Easy access means repairs are faster and your production does not stop for long.

Industrial Water Chiller Cost Factors

Initial vs. Long-Term Costs

When you buy an industrial water chiller, do not just look at the price. Later, you will pay for energy and regular care. These extra costs can be a lot.

-

Small-capacity units (5-10 tons) cost between $5,000 and $15,000.

-

Medium-capacity models (50-100 tons) can range from $20,000 to $50,000.

A smart buyer looks at the "Total Cost of Ownership." Choosing a high-efficiency Oumal chiller might cost more at first, but it saves thousands in electricity over the years.

Surprising Tips & Mistakes

Overlooked Features

Small features can make big differences in industrial water chiller systems.

|

Feature |

Description |

|---|---|

|

Digital Controls |

Digital controllers help you manage energy and improve how the chilling system works in real-time. |

|

Electronic Expansion Valves |

Keeps superheat steady and helps the compressor work less, saving up to 14% energy. |

You can make good choices for your business by following these tips. First, check how much cooling your industrial chiller can provide. Next, look at energy efficiency to help control temperature better. Finally, choose a manufacturer like Oumal that provides reliable support and quality engineering.

Summary of Lifecycle Impact for Industrial Chillers:

|

Aspect |

Impact on Lifecycle Cost |

|---|---|

| Energy Efficiency | Lower operational costs over years |

| Operational Lifespan | Fewer replacements for your high-quality water chiller |

Top Benefits of Using a Water Cooled Screw Chiller in Large-Scale Manufacturing

Top Benefits of Using a Water Cooled Screw Chiller in Large-Scale Manufacturing

You face constant pressure to maintain efficiency and product quality in large-scale manufacturing. Water cooled screw chillers deliver a high-performance solution by tackling common cooling challenges such as energy consumption, operational noise, and durability.

-

These chillers outperform air-chilled options, operate quietly, and excel in hot climates.

-

You benefit from robust construction and compact design, ideal for process cooling needs across industries.

|

Aspect |

Details |

|---|---|

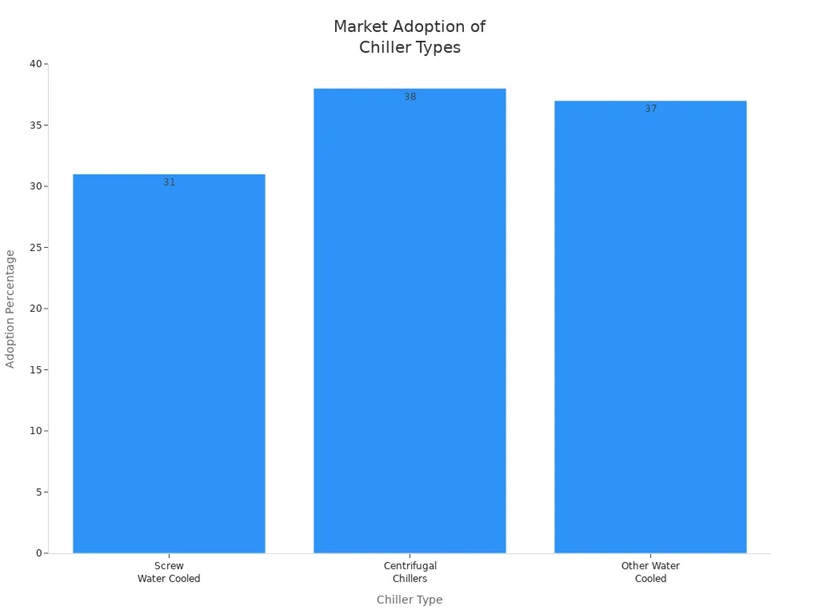

|

Market Share (2024) |

62.2% |

|

Key Industries |

Manufacturing, Pharmaceuticals, Data Centers |

|

Benefits |

Superior energy efficiency, lower operational costs, continuous cooling |

The OUMAL 70 ton water cooled screw chiller sets the standard for reliability and precise temperature control, helping you optimize productivity and safeguard product quality.

Key Takeaways

-

Water cooled screw chillers offer superior energy efficiency, leading to lower operational costs and significant savings on utility bills.

-

These chillers provide reliable temperature control, essential for maintaining product quality in industries like pharmaceuticals and food processing.

-

Modular design allows for easy expansion of cooling capacity, ensuring your system can grow with your manufacturing needs.

-

Regular maintenance of your chiller is crucial for peak performance and longevity, helping to minimize downtime and unexpected repairs.

-

Using water as a cooling medium reduces environmental impact, supporting sustainability goals while enhancing operational efficiency.

How a Water Cooled Screw Chiller Works

You rely on a water cooled screw chiller to deliver consistent and efficient cooling for your manufacturing processes. This system uses a vapor compression cycle to remove heat from your operations. The process starts when the twin-screw compressor draws in low-pressure refrigerant gas from the evaporator. As the screws rotate, they compress the gas, increasing its pressure and temperature.

The high-pressure, high-temperature refrigerant gas exits the compressor and enters the condenser. Here, it releases heat to the condenser water, causing the refrigerant to condense into a high-pressure liquid. The high-pressure liquid refrigerant then passes through an expansion valve, where it undergoes a rapid expansion, lowering its pressure and temperature.

The cooled refrigerant absorbs heat from your process water in the evaporator, completing the cycle. This continuous operation ensures your equipment and products stay within precise temperature ranges.

Key Features for Manufacturing

A water-cooled screw chiller offers several advantages that make it ideal for large-scale manufacturing. You benefit from a compact size, which allows for installation in facilities with limited space and reduces operational noise. The reliable screw-type compressors provide efficient cooling capacity for demanding applications, ensuring smooth start-ups and minimal impact on your power grid.

|

Feature |

Benefit |

|---|---|

|

Compact size |

Small footprint and quieter operation suitable for medium- to large-scale cooling. |

|

Reliable screw-type compressors |

Efficient cooling for large applications with smooth start-ups and reduced grid impact. |

|

Smart controls |

Intelligent monitoring and control solutions for cost-effective management and expansion. |

|

Intuitive operation |

User-friendly interface for easy monitoring and troubleshooting. |

|

Longer service life |

High-quality components ensure durability and cost-effectiveness over time. |

|

Better heat exchanging parts |

Efficient heat exchange design minimizes blockages and maximizes performance. |

|

Customizable for every application |

Tailored configurations to meet specific cooling requirements, enhancing versatility. |

You can use a water cooled screw chiller in a wide range of industries, including plastics, electronics, chemicals, printing, pharmaceuticals, and food distribution. This versatility, combined with advanced features like smart controls and durable components, ensures your manufacturing operation remains productive and cost-effective.

Energy Efficiency of Water Cooled Screw Chillers

You want to reduce your facility’s operating expenses while maintaining reliable cooling. A water cooled screw chiller delivers high efficiency by leveraging water’s superior heat transfer properties. Water absorbs and releases heat more effectively than air, which means your chiller uses less energy to achieve the same cooling output. This translates into significant savings on your utility bills.

The OUMAL 70 ton water cooled screw chiller exemplifies this advantage. Its advanced design and powerful twin-rotor screw compressor optimize energy consumption, allowing you to cool large-scale operations without excessive power draw. You benefit from a system that handles high capacities and integrates seamlessly with building management controls, further lowering your costs.

-

Water cooled screw chillers are engineered for high efficiency, which leads to reduced energy consumption.

-

You can rely on these chillers to manage large cooling loads, making them ideal for industrial applications.

-

Integration with smart control systems allows you to monitor and adjust performance, maximizing savings.

Tip: Regular maintenance of your chiller ensures peak performance and helps you sustain lower operating costs over time.

Optimized Energy Use in Industry

You need a cooling solution that supports your production goals and environmental commitments. Water cooled screw chillers offer enhanced energy efficiency, making them a preferred choice for manufacturers who prioritize sustainability and cost control. By using water as the cooling medium, these chillers achieve superior heat transfer, which boosts overall efficiency and reduces energy waste.

A water cooled screw chiller operates with advanced technologies, such as oil management systems and intelligent controls, that further improve energy use. You experience consistent cooling performance and extended equipment lifespan, which means fewer interruptions and lower maintenance costs. Compared to air-cooled alternatives, water cooled systems deliver more stable and reliable operation, helping you maintain optimal production conditions.

|

Feature |

Impact on Energy Efficiency |

|---|---|

|

Water as cooling medium |

Superior heat absorption and transfer |

|

Twin-rotor screw compressor |

High efficiency and stable performance |

|

Intelligent control system |

Optimized energy use and monitoring |

|

Durable components |

Longer lifespan and reduced energy waste |

You can trust a water cooled screw chiller to support your manufacturing processes with consistent, energy-efficient cooling. This technology not only lowers your operational expenses but also contributes to a greener, more sustainable facility.

Reliable Chiller Performance

You depend on stable temperature control to maintain quality and safety in your manufacturing processes. A water cooled screw chiller delivers consistent cooling, which is essential for industries where even minor temperature fluctuations can cause significant problems. You see this reliability in pharmaceutical manufacturing, where strict temperature control ensures drug efficacy and safety. In textile production, you prevent defects in dyeing and finishing by managing temperature precisely. Chemical processing plants rely on dependable cooling to keep equipment safe and prevent overheating during critical reactions. Cold storage warehouses maintain low temperatures to preserve perishable goods, while hospital surgical suites require stable conditions for patient safety and comfort.

|

Industry |

Evidence of Reliability |

|---|---|

|

Pharmaceutical Manufacturing |

Ensures drug efficacy and safety by maintaining strict temperature control during production and storage. |

|

Textile Industry |

Prevents defects in dyeing and finishing processes by managing temperature fluctuations effectively. |

|

Chemical Processing Plants |

Provides reliable cooling for critical equipment, ensuring safe operation and preventing overheating during reactions. |

|

Cold Storage Warehouses |

Maintains low temperatures to prevent spoilage of perishable goods, ensuring product safety and freshness. |

|

Hospital Surgical Suites |

Maintains stable temperature and humidity levels, crucial for patient safety and comfort during surgeries. |

You achieve reliable process cooling with advanced components and intelligent control systems. Modern chillers use inverter-driven screw compressors, which optimize operation and simplify maintenance. Two independent refrigerant circuits provide redundancy, so your system continues to operate even if one circuit requires service. Auto-adaptive controls adjust performance based on real-time conditions, while advanced algorithms minimize mechanical stress and improve reliability. Oversized roller bearings ensure durability under heavy loads.

|

Feature |

Description |

|---|---|

|

Inverter-driven screw compressors |

Optimized for reliable operation and easy maintenance with oversized bearings. |

|

Two independent refrigerant circuits |

Enhances reliability by providing redundancy. |

|

Auto-adaptive control |

Adjusts performance based on real-time conditions. |